IFF

| Max. flow | 360 m3/h |

| Differential head | 35 m wc |

Traditionally, kriek breweries brew real kriek beer a few times a year. They mix real cherries with the beer, so that the sugars and flavors of the cherries can be released into the beer and further fermentation can take place. In most cases, however, these breweries work daily with cherry or fruit concentrate, which is added to the beer.

Cherries usually have a hard skin, so it would take a long time for the flesh to release all of its flavors and sugars into the beer if they were simply mixed with the beer without pre-treatment. The challenge in this pre-treatment is to separate the flesh from the pit without damaging the pit, as this would give the beer a bitter taste.

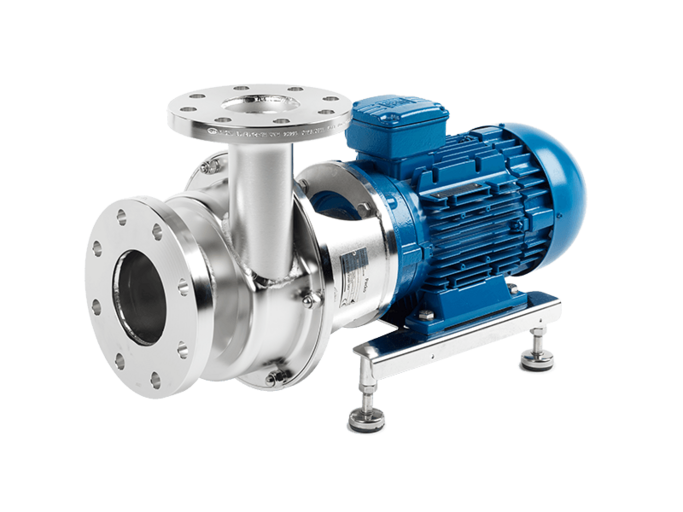

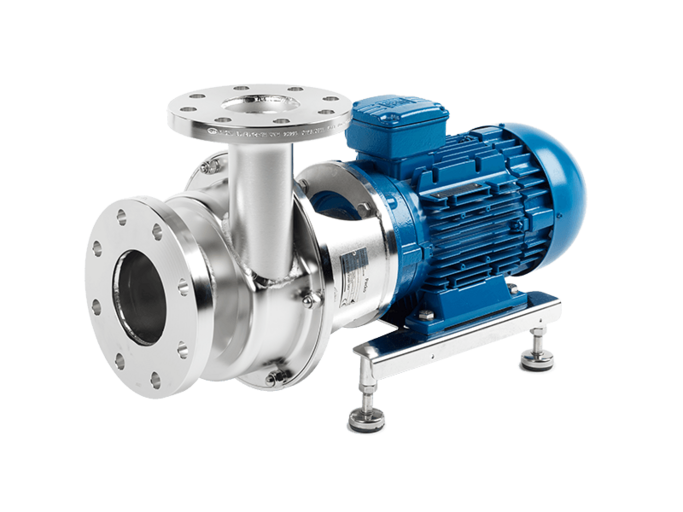

Mort Subite Brewery was looking for a solution to separate the flesh from the cherries without damaging the pits. They tried a number of different pump solutions, but none of these solutions were effective. Then they came to Packo. Packo offers a wide range of pumps for the food industry, including centrifugal pumps that are specifically designed for separating flesh from pits. Packo supplied two IFF in-line cantilever pumps with a vortex (semi-open) impeller to Mort Subite Brewery. These pumps have a large free passage, which allows the pits to be pumped through the pump, and a vortex impeller, which separates the flesh from the pits.

Normally, Packo pumps are selected at the BEP (Best Efficiency Point), so that as little energy as possible is put into the product. In this case, the pumps were selected away from the BEP to extend the residence time in the pump and thus increase the chance of impact by the impeller on the cherries.

Packo’s IFF cantilever pumps are also EC1935/2004 certified and easy to clean. This makes them perfect for use in the food industry. The pumps can also be perfectly cleaned during the CIP process after the batch.

Our experts can help you with the right pump for your process!

Packo’s IFF cantilever pumps have helped Mort Subite Brewery to find an efficient and hygienic way to separate the flesh from the cherries without damaging the pits. This has led to a better taste of the beer and higher productivity.

| Max. flow | 360 m3/h |

| Differential head | 35 m wc |