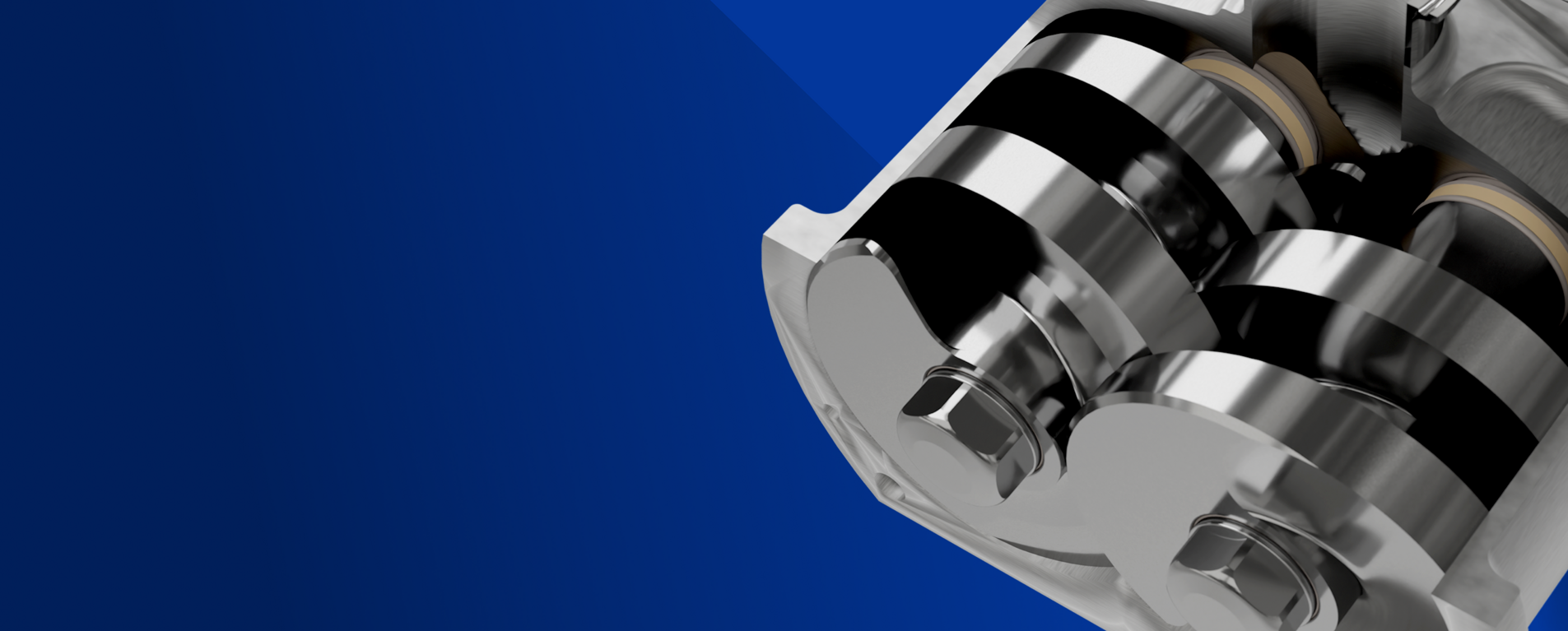

A twin screw pump is a type of positive displacement pump that consists of two intermeshing screws within a chamber. As the screws rotate, they move the fluid through the pump and create a vacuum at the inlet and pressure at the outlet. This allows the pump to handle fluids of different viscosities.

Twin Screw Pump Applications

Our Twin screw pumps are versatile and used in various industries due to their ability to handle different viscosities and materials. Here are a few examples of where our Packo twin screw pumps excel at:

- Sanitary Applications: Twin screw pumps are used for their ability to pump from very thin to very thick liquids, which is beneficial for reducing the number of pumps in a plant. They are ideal for CIP (Clean In Place) and CIP return pump functions due to their high suction capability for viscous products with solid particles.

- Food and Beverage Industry: They have been successfully used in food applications, particularly for pumping high viscosities like dough and fluids with changing viscosities, such as during CIP cleaning.

- Chemical Processing: Twin screw pumps are suitable for handling abrasive and shear-sensitive media, making them a good fit for chemical processing applications.

- Waste Water Treatment: These pumps are also used in waste water treatment for their ability to handle primary and activated sludge, as well as lime recirculation.

These applications demonstrate the flexibility and efficiency of twin screw pumps in handling a wide range of materials and conditions across different industries.

Why choose a twin screw pump?

Twin screw pumps are a popular choice for various applications due to their unique advantages. Here are three reasons why one might choose a twin screw pump:

- Versatility in Handling Fluids: Twin screw pumps are capable of handling fluids with a wide range of viscosities, from very thin to very thick liquids. This makes them suitable for industries that process different types of materials.

- Gentle on Shear-Sensitive Media: These pumps offer pulsation-free and gentle pumping, which is crucial for shear-sensitive media. This ensures that the integrity of the material being pumped is maintained, preventing damage to delicate substances.

- Hygienic Design: Twin screw pumps are designed with hygiene in mind, making them ideal for industries where cleanliness and sanitation are paramount, such as the food and pharmaceutical industries. They are easy to clean and maintain, which helps in meeting strict hygiene standards.