General Industrial Series

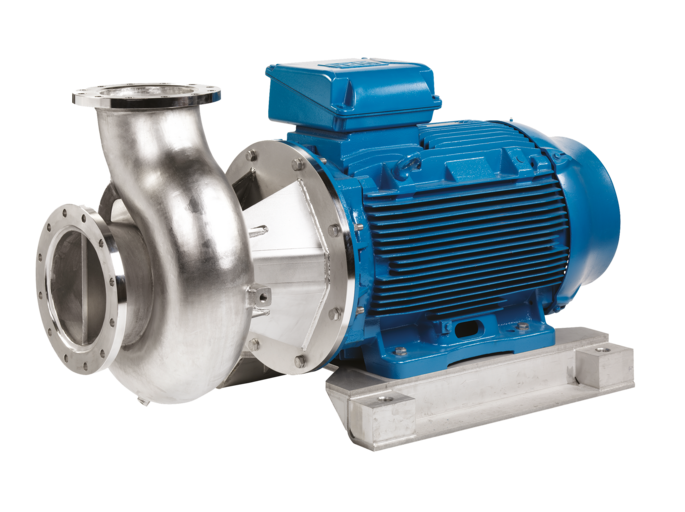

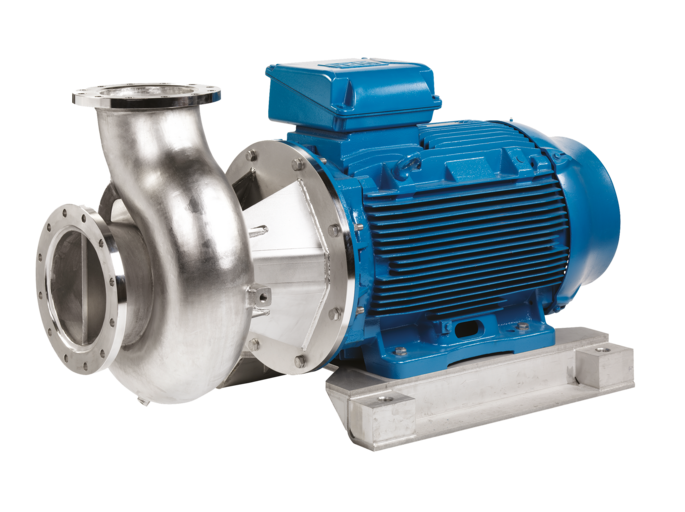

The Packo general industrial pump series excel with their high efficiency and low NPSH. The close-coupled modular construction of these pumps uses standardized...

| Max. flow | 1800 m3/h |

| Differential head | 220 m wC |

Discover the capabilities of a centrifugal pump and

how it can be the right solution for your application.

Do you have questions about our centrifugal pump range?

One of our pump experts is here to support you.

Our range of Packo centrifugal pumps are known for their outstanding craftsmanship and technological innovation. Made from stainless steel, they are suitable for a range of applications ranging from industrial, hygienic, to pharmaceutical and more. Below you will find everything about a centrifugal pump, its working principle, benefits and reasons to use and a breakdown of the applications where this type of pump excels at.

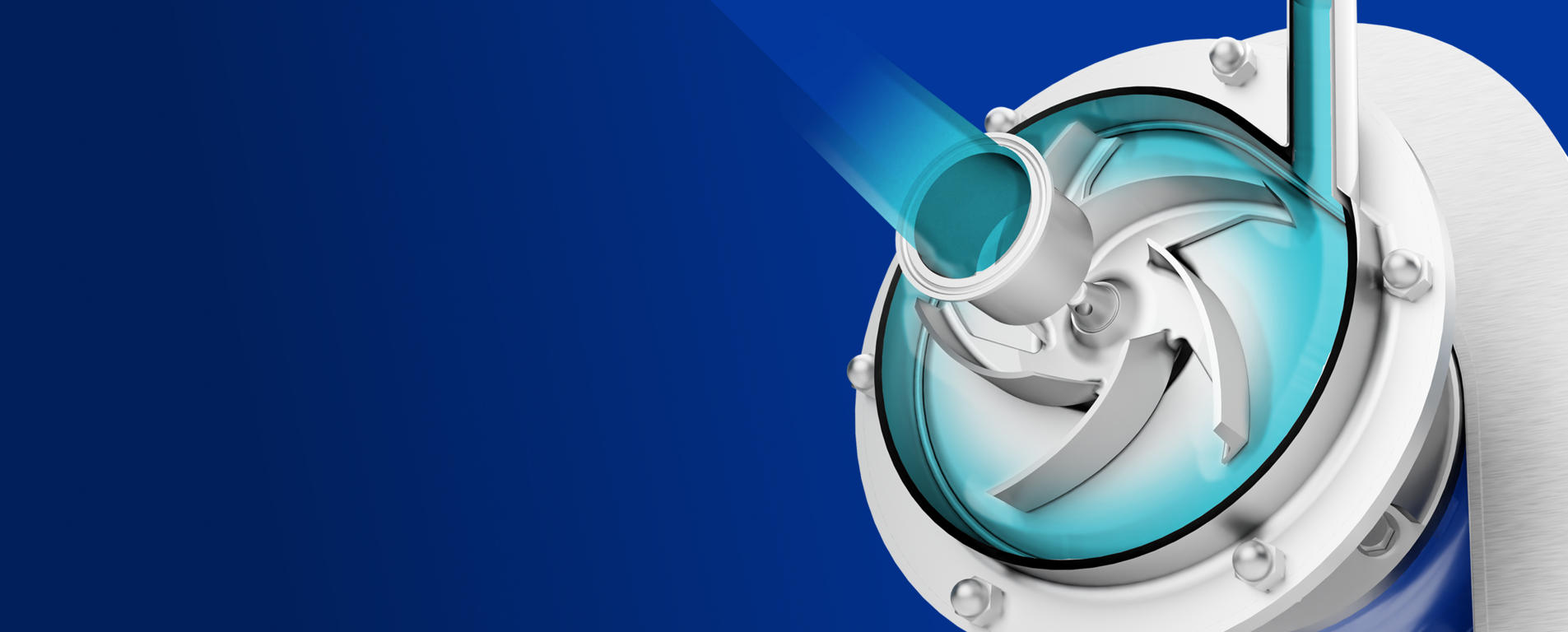

A centrifugal pump works on the principle of a rotating impeller within a stationary pump housing. The impeller is connected to a shaft and powered by a motor. As the impeller turns, it moves the liquid out of the pump through centrifugal force, exiting through the discharge flange.

A centrifugal pump operates on the principle of centrifugal force to move fluid. How does this translate to operation?

Do you need help? Our pump experts are there for all your questions!

The Packo general industrial pump series excel with their high efficiency and low NPSH. The close-coupled modular construction of these pumps uses standardized...

| Max. flow | 1800 m3/h |

| Differential head | 220 m wC |

The Packo sanitary pump series are designed for use in the most demanding hygienic applications in almost all industries such as dairies, breweries, beverage industry, distilleries, etc. They are the ideal solution for filtration applications, pasteurisation, evaporating systems, yeast propagation and for CIP cleaning systems as well.

| Max. flow | 1800 m3/h |

| Differential head | 220 m wC |

Choosing a Packo centrifugal pump offers several advantages