Static and Dynamic Mixers

Discover the capabilities of static and dynamic mixers

and how they can be the right solution for your application.

Do you have questions about our static and dynamic mixers?

One of our pump experts is here to support you.

What are Static mixers?

Static mixers are immobile units that include stationary elements such as baffles, blades, or elements arranged in a specific pattern within a pipe or tube. These elements cause the fluid to divide and recombine, resulting in increased levels of turbulence and mixing in a continuous flow, without the need for any moving parts or external power source. They are typically lower in cost, require no external power, and have low energy consumption and operating costs due to having no moving parts.

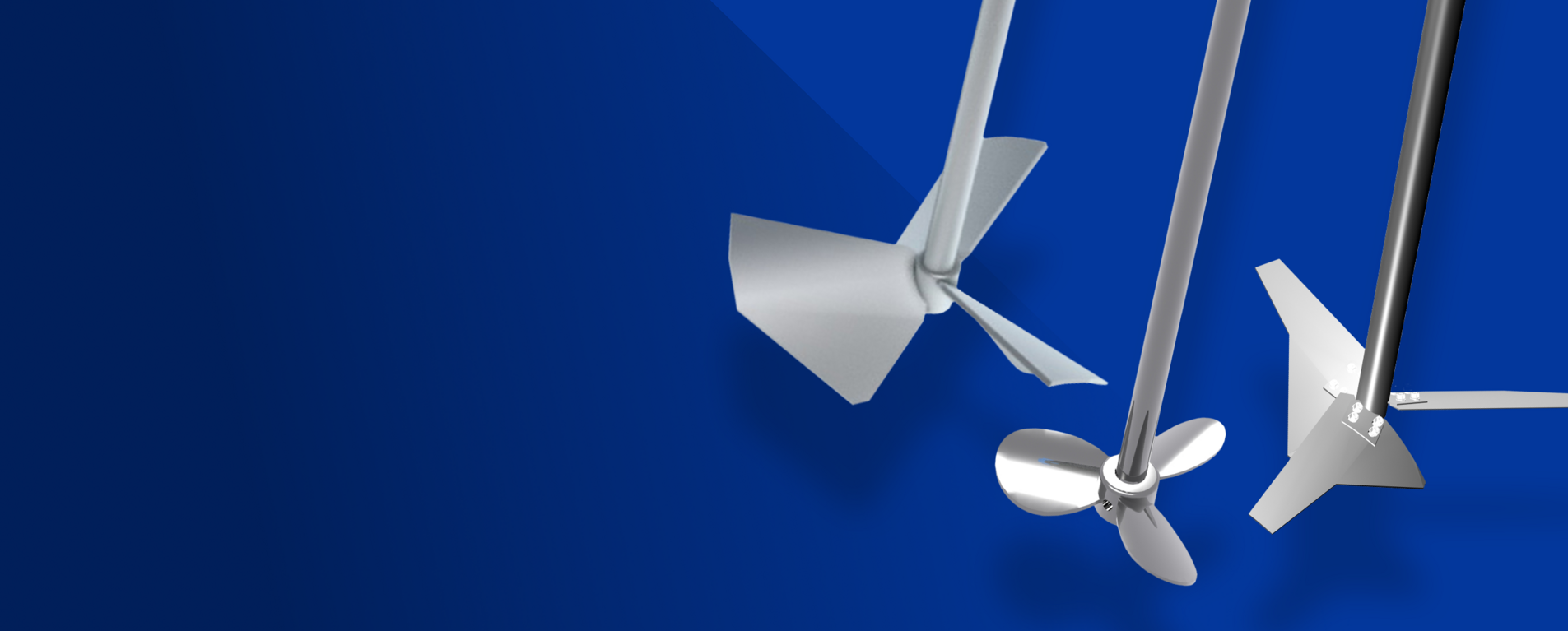

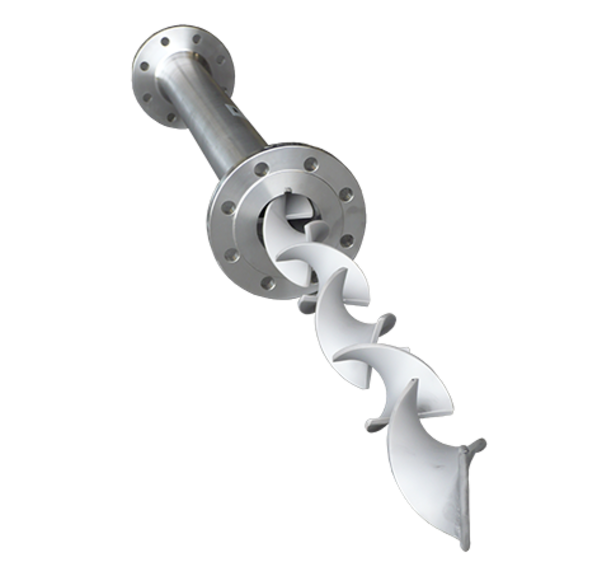

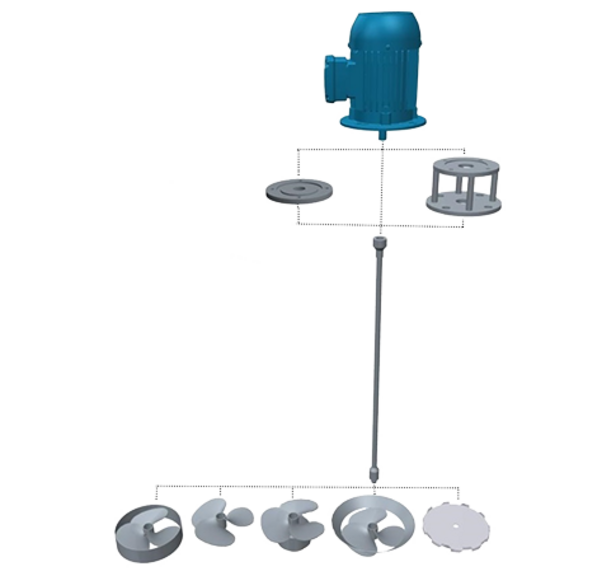

What are Dynamic Mixers?

Dynamic mixers, on the other hand, require electrical power input to create turbulence and mixing within the fluid. They use a rotating shaft and impellers to blend liquid components, often spinning at high speed. Dynamic mixers are ideal for batch blending high-viscosity fluids or when a homogenous mixture is required in a tank. However, they typically require more space and inspection points for installation, increasing the complexity and cost of installation.

Benefits of Static and Dynamic Mixers

- Enhanced Process Control

- High Mixing Efficiency

- Customizable Solutions

- Robust and Durable Design

Applications of Static Mixers

- Chemical Processing: Static mixers are used for mixing chemicals in small tanks, typically ranging from 100 to 500 liters. They are ideal for applications that require precise and consistent mixing without the need for moving parts.

- Water Treatment: Static mixers are employed in water treatment processes to ensure thorough mixing of chemicals and other additives. This helps in achieving uniform water quality and effective treatment.

- Food and Beverage: In the food and beverage industry, static mixers are used for blending ingredients, ensuring consistent product quality. They are particularly useful in applications where hygiene and cleanliness are critical.

Applications of Dynamic Mixers

- Water Treatment: Dynamic mixers are used in water treatment plants for mixing chemicals and additives to ensure uniform water quality. They are particularly effective in wastewater treatment and drinking water treatment plants.

- Food and Beverage: In the food and beverage industry, dynamic mixers are used for precise ingredient dosing and blending. They are ideal for applications such as marinades, seasoning, syrup blending, and nutrient fortification.

- Pharmaceuticals: Dynamic mixers are essential in the pharmaceutical and biotech industries for tasks such as buffer and media preparation, dispensing nutrients for microbial cultures, tablet coating, and bottle filling.