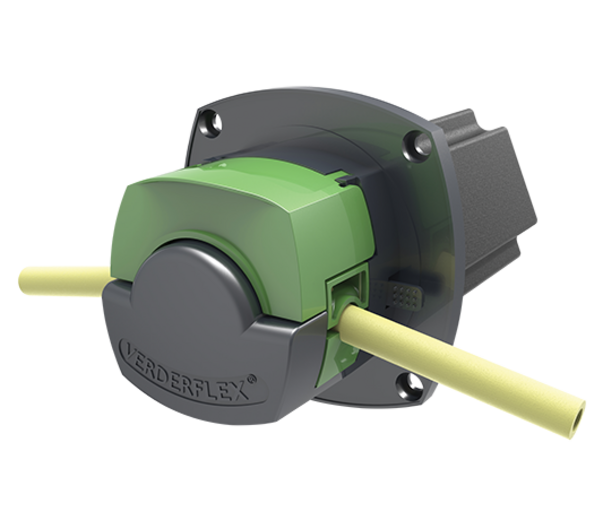

Verderflex Ds500

The Ds500 cased tube pump, discover the precision, reliability, and flexibility by joining the growing community of IoT enabled Ds500 Verderflex customers. Explore our...

| Max. flow | 30 l/h |

| Max. discharge pressure | 7 bar |

Discover the capabilities of a peristaltic pump and

how it can be the right solution for your application.

Do you have questions about our peristaltic pump range?

One of our pump experts is here to support you.

Our range of Verderflex peristaltic pumps are engineered to be reliable pumps used with a large variety of fluids in several industries and for different types of applications. A key benefit offered when utilizing a Verderflex peristaltic pump is the reduction of maintenance and downtime for your process. Below you will find an overview about peristaltic pumps including the working principle, advantages, and applications, to find why a peristaltic pump can be the right pump for your application.

A peristaltic pump operates on the principle of positive displacement, where a rotating shoe or roller compresses and decompresses a flexible hose or tube to create a seal. The decompression draws the fluid in, and as the rotor turns, the seal moves along the tube, displacing the fluid into the discharge line without the need for valves, seals, or glands. The liquid is totally contained within a flexible hose or tube fitted inside the pump casing. These would be the pump's only consumable part. All Verderflex pumps can be used in hygienic applications thanks to several food grade hoses and tubing.

Find out more about how peristaltic pumps work below!

The Ds500 cased tube pump, discover the precision, reliability, and flexibility by joining the growing community of IoT enabled Ds500 Verderflex customers. Explore our...

| Max. flow | 30 l/h |

| Max. discharge pressure | 7 bar |

The compact Verderflex iDura is a complete “ready to use", reversible Dura hose pump with factory fitted hose burst protection and an IP66 inverter. IoT enabled with remote assistant.

| Max. flow | 25985 l/h |

| Max. discharge pressure | Consult Verderflex |

The Microdos range of OEM peristaltic tube pumps are suitable for integration into systems for dosing, dispensing, vending, transfer and bottle filling.The units are...

| Max. flow | 2200 ml/min |

| Max. discharge pressure | 3 bar |

When choosing which peristaltic pump to utilize, there are a few considerations to be made that will affect greatly the effectiveness of the pump in question.

Chemical compatibility: when choosing a peristaltic pump, it is essential to choose the right pump for your application. Chemical compatibility is an important one as we have different Verderflex pumps suited for different applications, and for different chemicals applications. More specifically, the different tubes and hoses offered with the pumps will dictate which chemicals they're best suited to work with. Each material has its own resistance profile against various chemicals. For instance, Hypalon® is known for its resistance to a wide range of chemicals, while there are also natural rubber, nitrile, EPDM suited for other applications.

Pressure and Flow rate: the flow rate of a peristaltic pump is essential and will depend on the media you are looking to pump. Verderflex offers pumps suited both for high flow and high-pressure applications, but also smaller pumps with lower flow rates and pressures, ideal for precise dosing applications.

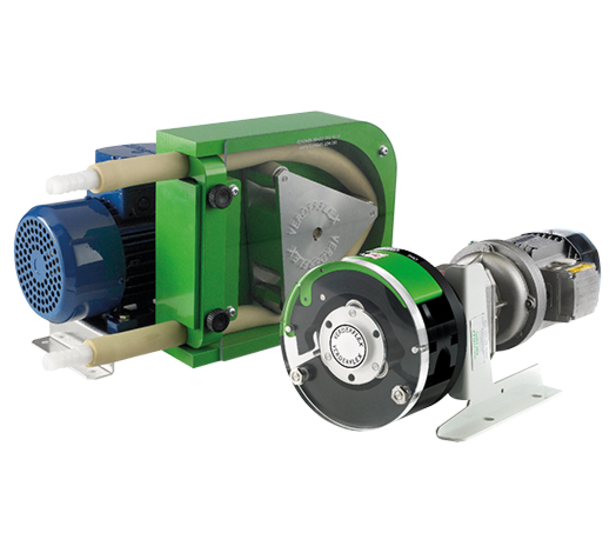

Verderflex offers two types of peristaltic pumps. A peristaltic hose pump and a peristaltic tube pump. Both types of pumps are part of Verderflex’s comprehensive range of peristaltic pumping solutions, which are known for their quality, efficiency, and ability to handle a variety of challenging pumping applications.

A peristaltic tube pump works by alternating compression and relaxation of a tube, drawing fluid in and propelling it away from the pump. A rotating shoe or roller passes along the length of the tube, creating a seal between the suction and discharge sides of the pump. As the pump’s rotor turns, this sealing point moves along the tube, displacing the product into the discharge line. The tube recovers after the pressure has been released, creating a vacuum that serves as the priming mechanism, drawing the product into the suction side of the pump. This results in a powerful self-priming positive displacement action. The Verderflex Rapide is an example of a tube pump, known for its compact design and ease of use, requiring no tools for tube changes, making it a cost-effective solution for industrial applications.

Hose pumps operate on a similar principle to tube pumps but use a hose instead of a tube. The Verderflex Rollit series, for example, are lubricant-free peristaltic hose pumps designed for applications in the chemical industry, food and pharma, construction, environmental industry, and many others. These pumps are known for their gentle pumping of sensitive media, self-priming capabilities, and the ability to safely run dry. They can handle high-viscous, abrasive, and aggressive media with ease, as the hose is the only wetted part, eliminating the need for seals, flaps, and valves.

A peristaltic pump, and its working principle, can be utilized in several different industries. Some of these industries include, but are not limited to, chemical processing, pharmaceuticals, food and beverage, and water treatment, due to a peristaltic pump's efficiency and the sanitary conditions it provides for sensitive fluids.

Verderflex pumps allow the operator to choose between various peristaltic hose and tube pump options. This variety empowers any process plant to deploy Verderflex peristaltic pumps as single source of supply and importantly drastically reduce maintenance spares. Furthermore, Verderflex is the only peristaltic pump manufacturer with asset management IoT remote access software to monitor each pump performance and obtain data to plan and schedule maintenance intervals. Verderflex peristaltic pumps are known to be safe, reliable, energy efficient whilst transferring high density, both aggressive and or corrosive liquids any (including ATEX) environments.