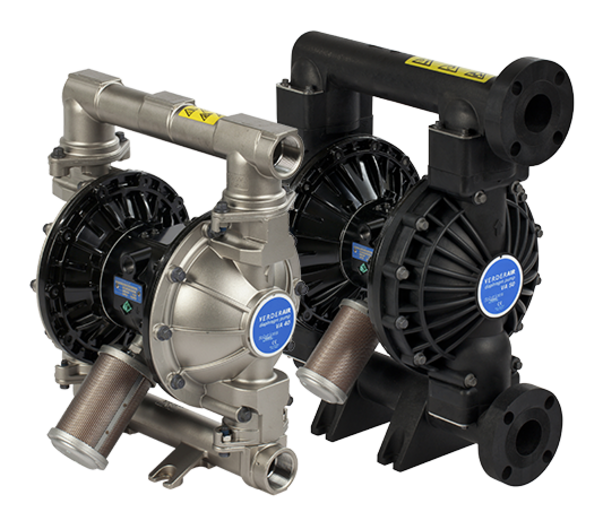

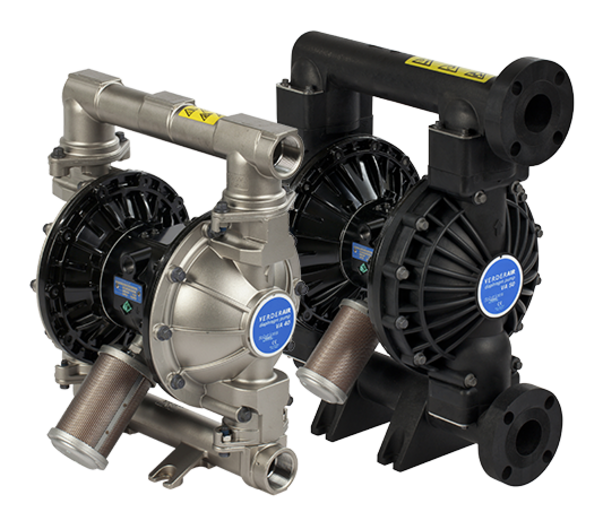

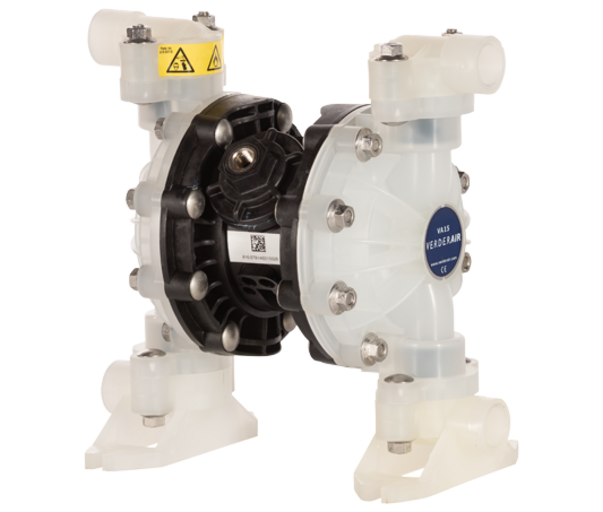

Verderair VA

Available in metallic and non-metallic construction with many different wet-side materials, the VA range is compatible with chemically-aggressive and abrasive media.

| Max. flow | 1200 l/min |

| Max. discharge pressure | 8,6 bar |

Verderair pumps are the most efficient diaphragm pumps. Our Verderair pumps are designed and produced within our own production site. With a selection ranging from electric diaphragm pumps to air operated diaphragm pumps, we can help you find the right pump for your application.

The Verderair diaphragm pumps are the best solution for transfer applications that require more than just fluid to be handled. The range is excellent for viscous or sticky media, slurry and solids. The Verderair series offers diaphragm pumps, varying in material (metallic, non-metallic, conductive) to drive principle (electric, pneumatic).

Our experts can help you with the right pump for your process!

Available in metallic and non-metallic construction with many different wet-side materials, the VA range is compatible with chemically-aggressive and abrasive media.

| Max. flow | 1200 l/min |

| Max. discharge pressure | 8,6 bar |

The Verderair PURE is designed for heavy-duty operation, harsh chemicals and severe process conditions.

| Max. flow | 660 l/min |

| Max. discharge pressure | 7 bar |

The Verderair e-PURE electrically driven double diaphragm pump uses a new kind of technology for diaphragm pumps. This pump series works according to a horizontal...

| Max. flow | 100 l/min |

| Max. discharge pressure | 5 bar |

Our Verderair HC-PURE pumps are specifically designed with ultimate cleanibilty in mind which ensures hygienic durability for your pumps.

| Max. flow | 465 l/min |

| Max. discharge pressure | 7 bar |

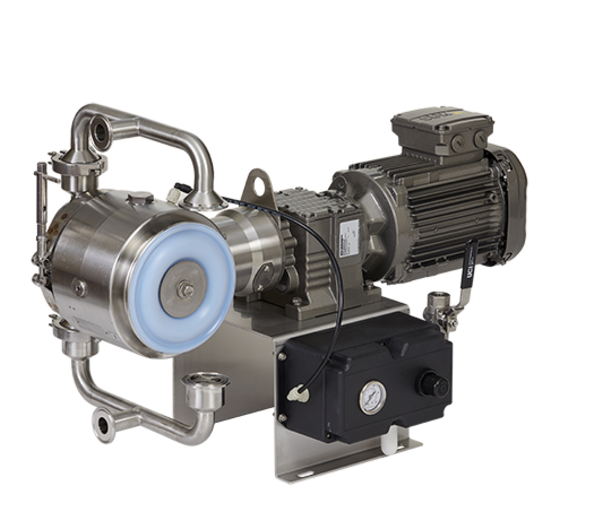

The Verderair HI-CLEAN pumps are designed for operation in hygienic, dairy, cosmetic and food processing applications.

| Max. flow | 870 l/min |

| Max. discharge pressure | 8 bar |

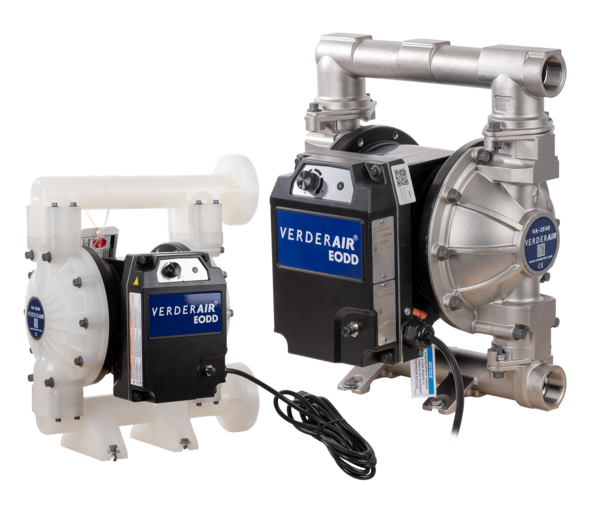

The 2nd generation of Verderair EODD pumps (Electric Operated Double Diaphragm pumps) combines all advantages of an AODD with the energy efficiency of an electrically...

| Max. flow | 454 l/min |

| Max. discharge pressure | 6.9 bar |

The redesigned Verderair Hi-Clean limits the number of tri clamp connections which come into contact with the fluid which simplifies the disassemble and assemble of the pump and therefore also limits the risk of contamination

| Max. flow | 378 l/min |

| Max. discharge pressure | 7 bar |

The Verderair CONT-EX is made of conductive polyethylene, standard ATEX certified and available in 4 sizes.

| Max. flow | 105 l/min |

| Max. discharge pressure | 7 bar |

The Verderair high pressure series is especially suitable for charging filter presses.

| Max. flow | 189 l/min |

| Max. discharge pressure | 17,2 bar |

A dual port diaphragm pump (split manifold) allows the pump chambers to operate as two different pumps.

| Max. flow | 2x30 l/min |

| Max. discharge pressure | 7 bar |

An AODD is an Air Operated Double Diaphragm pump and an EODD is an Electric Operated Double Diaphragm pump. AODD pumps are driven by compressed air and EODD pumps are driven by a motor.

A diaphragm pump, also knows as a membrane pump, is a positive displacement pump that enables users in industries to standardize on a pump type that is suitable for a wide variety of fluids. The only requirement is compressed air supply. For more information, please visit our extended technology page.

Verderair pumps are air operated diaphragm pumps (AODD), delivering a smooth, reliable flow for all circumstances. The air valves design guarantees a perfect, non-stalling operation, even at low pressure. The air valves do not need any lubrication. Thanks to their unique design, the pumps are able to handle very abrasive and/or viscous products.

Yes, spare parts are available to order for this pump. We offer maintenance kits, repair kits, dampeners, flow stop valves and all other relevant accessories. You can find more about spare parts here.

In the early 1970s, Verder started selling air operated diaphragm pumps. Verder had the sole representation for Europe of a number of renowned American brands, and also some European ones. During the following years, Verder built up a good reputation with its knowledge of diaphragm pumps and their specific applications. Due to the excellent market knowledge, however, it also became clear that the manufacturers built the pumps according to a solid but rigid construction, and that wishes from the end-users to adapt the pumps to more specialized applications weren’t taken into account.

Verder was listening to its customers and therefor developed its first own double diaphragm pump and included customers specifications: The CONT-EX. It was launched on the market in 1993. An advanced pump for that time, with conductive plastics as a wetted part, and with a sleek design. Compact, but rigid, and the series could be used for the most diverse liquids and chemicals.

In 1997 Verder created a complete line of double diaphragm pumps: VERDERAIR. The Verderair pumps are manufactured in Belgium and in Poland. Ever since then Verder has sold more than 800,000 diaphragm pumps all over the world.

Verderair has a wide range of industrial double diaphragm pumps. With more than 11 material combinations, several ATEX certificates, EC 1935/2004, CE, EN2.1, EN3.1and a large accessories program the industrial diaphragm pump line can be found in all branches of industry; from stand-alone pump to a complete production line with up to 80 pumps in a row in, for example, the paint industry.

Verderair also manufactures a complete line of hygienic double diaphragm pumps. With a surface roughness from 3.2 up to even 0.8 the hygienic diaphragm pumps are available for standard hygienic applications, as well as hi-spec applications. Certifications are a.o. FDA, USP Class VI. Special models for bone transport and horizontal models and models with flapper valves complete the line.

The Verderair EODD pumps (Electric Operated Double Diaphragm pumps) combines all advantages of an AODD with the energy efficiency of an electrically driven pump. Unique is the automatic stalling of the membranes against a closed discharge.

On top of that the pumps are ideal for applications that require low pulsations and a smooth flow due to the low pulse mode. The pumps are available in metallic and non-metallic materials, to be tailored for applications demanding resistance to aggressive chemicals and abrasive fluids.