Verderflex Ds500

The Ds500 cased tube pump, discover the precision, reliability, and flexibility by joining the growing community of IoT enabled Ds500 Verderflex customers. Explore our...

| Max. flow | 30 l/h |

| Max. discharge pressure | 7 bar |

Battery production is an essential component of the modern world, powering everything from smartphones to electric cars. However, the production of batteries requires a significant amount of energy and resources, making it crucial to optimize the manufacturing process for efficiency and sustainability. In battery production, pumps are fundamental to transfer ingredients in various stages of the production process. Pumps play a critical role to maintain the chemistry of materials in mixing, the transportation of materials, and control of fluid flow within the production line. In this article, we will explore the various ways in which pumps are used in battery production and how they contribute to the overall efficiency and sustainability of the process.

The lithium-ion battery value chain can be divided in three phases:

· Upstream (from raw materials to processed lithium compound)

· Middle stream (battery production)

· Downstream (usage of the battery & battery recycling)

If you need help deciding which pump is best for your application, please feel free to contact our pump experts

'The electric vehicle (EV) market is experiencing unprecedented growth, driven by the global shift towards sustainable energy and transportation. At the heart of this revolution is the EV battery, a component that has become synonymous with innovation, efficiency, and environmental stewardship. The manufacturing process of these batteries ....'

As Verder Liquids, we are aware how the pump selection in battery manufacturing can be challenging., Whilst ensureing quality and safety, efficiency is also a crucial part of which pump to choose. We have combined all our knowledge into this whitepaper for your help. To read more: please fill in your contactdetails and you can download the whitepaper immediately.

The Ds500 cased tube pump, discover the precision, reliability, and flexibility by joining the growing community of IoT enabled Ds500 Verderflex customers. Explore our...

| Max. flow | 30 l/h |

| Max. discharge pressure | 7 bar |

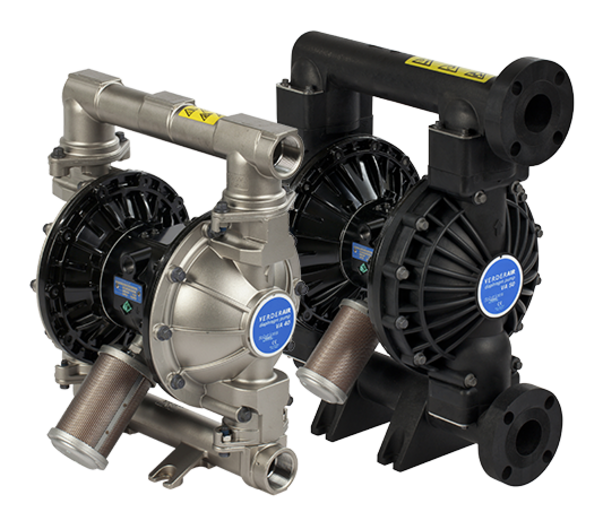

Available in metallic and non-metallic construction with many different wet-side materials, the VA range is compatible with chemically-aggressive and abrasive media.

| Max. flow | 1200 l/min |

| Max. discharge pressure | 8,6 bar |

The compact Verderflex iDura is a complete “ready to use", reversible Dura hose pump with factory fitted hose burst protection and an IP66 inverter. IoT enabled with remote assistant.

| Max. flow | 25985 l/h |

| Max. discharge pressure | Consult Verderflex |

The Verderair PURE is designed for heavy-duty operation, harsh chemicals and severe process conditions.

| Max. flow | 660 l/min |

| Max. discharge pressure | 7 bar |

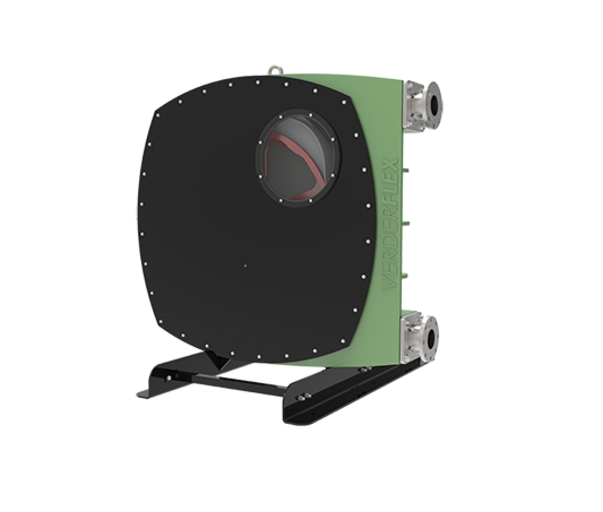

The Verderflex range of 'VF' industrial peristaltic hose pumps are excellent at handling difficult media such as slurry, sludge, suspensions, solid-laden and thickened, viscous fluids.

| Max. flow | 90000 l/h |

| Max. discharge pressure | 16 bar |

The Verderair e-PURE electrically driven double diaphragm pump uses a new kind of technology for diaphragm pumps. This pump series works according to a horizontal...

| Max. flow | 100 l/min |

| Max. discharge pressure | 5 bar |