How do peristaltic pumps work?

Peristaltic pumps are a type of positive displacement pump used for pumping a variety of fluids. The fluid is contained within a flexible hose or tube fitted inside the pump casing. The actual pumping principle, called peristalsis, is based on alternating compression and relaxation of the hose or tube, drawing content in and propelling product away from the pump.

A rotating shoe or roller passes along the length of the hose or tube creating a temporary seal between the suction and discharge sides of the pump. As the pump’s rotor turns this sealing pressure moves along the tube or hose forcing product to move away from the pump and into the discharge line. Where the pressure has been released the hose or tube recovers creating a vacuum, which draws the product into the suction side of the pump, the priming mechanism.

Combining these suction and discharge principles results in a powerful self-priming positive displacement action.

Proportional dosing

The perfect seal between the two sides of the pump means that there is no product slip, when coupled with the pump’s linear speed-flow characteristic, it makes peristaltic pumps ideal for dosing.

No cross-contamination

The liquid being pumped never comes into contact with any moving parts because it is totally contained within the reinforced hose or tube. Additionally, as the pumped liquid is totally contained within the hose or tube, this makes a peristaltic pump a hygienic pumping solution with zero chance for contamination. This also reduces maintenance time as the hose or tube is the only wearing part.

Advantages Peristaltic Pumps

Every peristaltic pump features a flexible hose or tube, giving an open flow path which gives a high resistance to abrasion and permits the easy flow of solids, high S.G. and viscous media. Despite the capacity for pumping some of the world's most difficult fluids, the pump itself delivers a gentle pumping action, making it suited for shear-sensitive product such as polymers and even whole fish!

The flow of the pump is proportional to the speed, making it suited for dosing. As a peristaltic pump is available both in large and small models, it may be used from laboratories to mining applications.

The hose prevents cross-contamination. For safety and peace of mind, the pump has no mechanical seals and in the event of a hose rupture, contains the fluid safely.

Peristaltic pumps - Features and Benefits

Peristaltic pumps provide excellent problem solving pumping solutions especially when the product being pumped is particularly abrasive, corrosive or viscous. Their lack of valves, seals and glands makes them inexpensive to maintain the only maintenance item is the hose or tube. Peristaltic pumps also have a gentle pumping action, ideal for shear sensitive polymers and fragile cell cultures. Lastly, the only part of the pump in contact with the fluid being pumped is the interior of the tube or hose, making it easy to sterilise and clean the inside surfaces of the pump.

-

Seal-less design

-

Low maintenance costs

-

Dry running and self-priming

-

Gentle pumping action

-

High suction lift

-

Abrasion resistant

-

Solids handling

-

Reversible

-

No slip

-

Accurate dosing

Types of Peristaltic Pumps

There are two types of peristaltic pumps: hose pumps and tube pumps. Tube pumps are perfect for lower flow rates, are fully programmable, with the option of multiple heads, while hose pumps are perfect for pumping highly solid content.

How are peristaltic pumps used?

Peristaltic pumps are used in a variety of industries. They are often found pumping slurry with high solid content from the mining industry, ad and bio gas and sewage facilities where there are highly abrasive, gritty and viscous fluids. The tube pumps are used more for chemicals or in a laboratory setting.

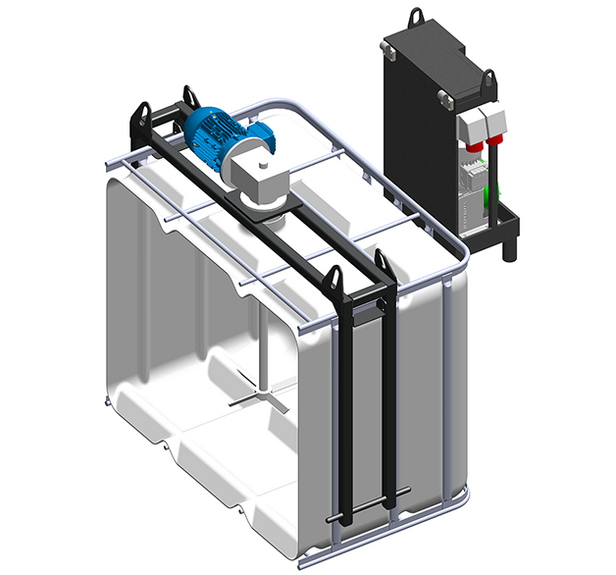

Verderflex hose and tube pumps

Verderflex pumps stand apart from their competitors: reliable innovative, high performance, peristaltic pumps that pump difficult products in tough conditions.

Verderflex pumps are renowned for providing top-quality solutions to an array of problems, within process industries around the world. Used in Original Equipment Manufacture as custom solutions that can be incorporated wherever accurate dosing is required. The Vantage 5000 models are easily programmable tube pumps and ideal for use with chemicals or in a laboratory setting. This range is complimented by the industrial tube pump range. Specifically designed to be used in hazardous areas, they provide a compact pumping solution for automated systems as standalone pumps or as part of Original Equipment Manufacture. These pumps have multiple power options and quick and easy tube change features. A range of tube materials are available to handle a range of different chemicals as well as hygienic options for food and beverage dispensing.

The Verderflex Dura and Verderflex VF hose pumps reliably pump the toughest fluids and are often found pumping slurry with high solid content from the mining industry to water plants.

The hose is the most important feature of any hose pump and Verderflex has designed its hose to be the longest lasting in the market, capable of withstanding corrosive and abrasive applications. The Verderflex hose can also be used in many other peristaltic pumps on the market, for more information visit the hose page.

Due to the often hazardous nature of the products pumped by Verderflex hose pumps, the range has been designed to provide maximum safety to the workforce and environment. Both the VF & the Dura’s hose connection is disaster-proof, totally containing the hose inside the pump casing – unlike other peristaltic pumps, eliminating any danger.

Verderflex hose pumps are incredibly accurate at dosing: they offer repeatable accuracy of ±1% without any slip. They also have a vacuum capability of 95% or a 9.5m / 31’ lift of water. Our largest peristaltic hose pump can pump 90m3/hour or 390 US GPM at pressures up to 16 Bar or 230 PSI.

Want to know more about how Verderflex pumps can help you?

Do you need help? Our pump experts are there for all your questions!