Pumps for Candy Production

From chocolate, to gummies, hard candies, and more, candy manufacturing is a process where hygiene, and the right control of certain variables such as flow and temperature are essential to the quality of the end product. This is where our Lobe Pumps excel.

The Candy Production Process

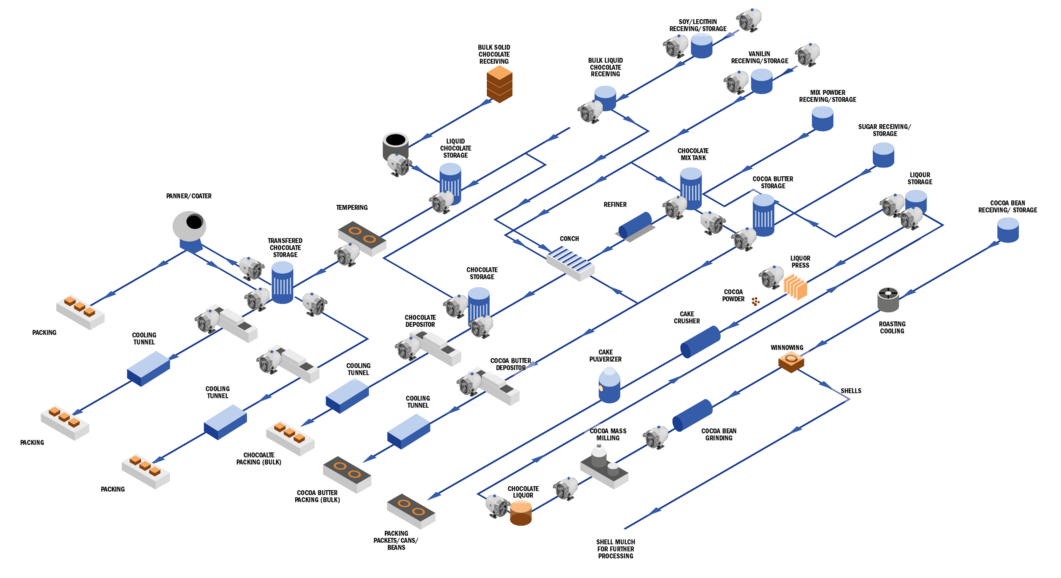

Candy manufacturing will look different for different types of candies. Despite this, there are various steps within the process that look the same irrelevant of the product. All ingredients, such as sugars, cocoa beans, soy lecithin, and more, begin in their respective storage units, where they begin to be moved to their first steps in production. These ingredients then undergo different treatments such as mixing, pressing, cooking, tempering, and cooling, to name a few. Pumps play a crucial role in the transfer of the fluids from one step to the next. The following can be visualized in the process map for chocolate production below.

Interested in a Pump for Candy Manufacturing?

One of our experts is here to help you.

Our Pumps for Candy Manufacturing

Chocolate Production Process Map

Featuring Packo Lobe Pumps

Why a Lobe Pump?

Different types of pumps provide different benefits when manufacturing candy. Why should you switch to a lobe pump?

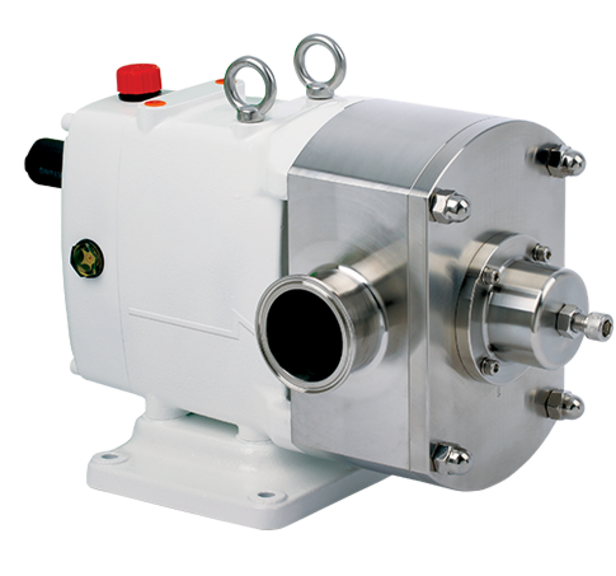

- Hygiene: Our lobe pumps are designed to meet the highest hygiene standards, making them ideal for candy processing. The utilizaiton of Stainless Steel is highly beneficial, as it is non-porous and smooth, making it much less likely to harbor bacteria and perfectly cleanable, easily cleaned in place (CIP).

- Gentle handling: in candy production, the end product might include solid pieces such as fruit or nuts. Lobe pumps provide gentle handling that will ensure that the mix maintains its integrity, and the product quality high, even with high viscosity mixtures.

- Low shear: a candy's texture is crucial, this is why candy production requires equipment that will not affect this in a negative manner. Lobe pumps are known for providing low shear, making them perfect for this application.

Lobe pumps, such as the Packo ZL, are the ideal choice for candy manufacturing. Their ability to maintain a product's quality high, with different viscosities, consistent temperatures, while providing gentle handling through the pumping process makes them the perfect solution for this application. Their perfect cleanability will always ensure you are meeting the hygienic standards and that your operations have minimum downtimes.