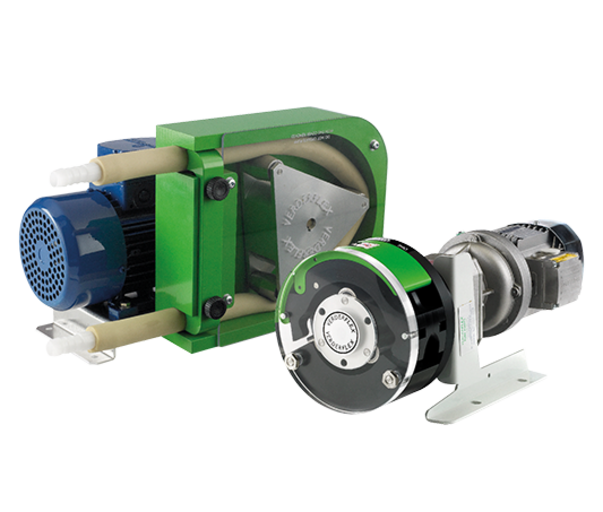

Verderflex Ds500

The Ds500 cased tube pump, discover the precision, reliability, and flexibility by joining the growing community of IoT enabled Ds500 Verderflex customers. Explore our...

| Max. flow | 30 l/h |

| Max. (discharge) pressure | 7 bar |

Verderflex® peristaltic pumps are extremely robust pumps, ideal for heavy duty operations on intermittent or continuous duty cycles. They are a simple to use, easy to control, versatile and reliable way to pump liquids.

Verderflex manufactures peristaltic pumps, the ideal solution for difficult to pump liquids, abrasive, viscous or solids laden slurries, dosing chemicals and gently transferring fragile cell cultures. These range from small OEM tube pumps through precision dosing and dispensing pumps to the world’s largest high pressure hose pumps for very heavy duty applications.

Do you need spare parts or accessories for your Verderflex pump? You can request what you need below!

Our experts can help you with the right pump for your process!

The Ds500 cased tube pump, discover the precision, reliability, and flexibility by joining the growing community of IoT enabled Ds500 Verderflex customers. Explore our...

| Max. flow | 30 l/h |

| Max. (discharge) pressure | 7 bar |

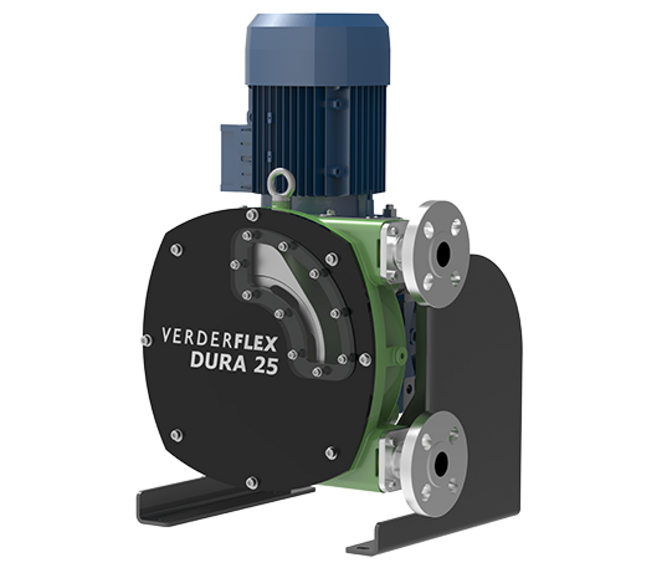

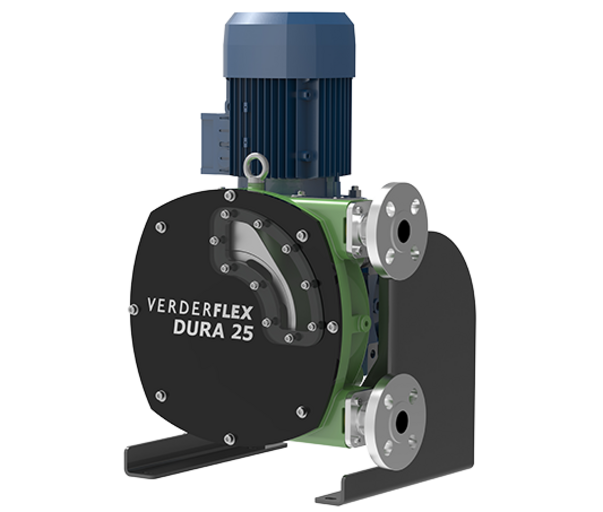

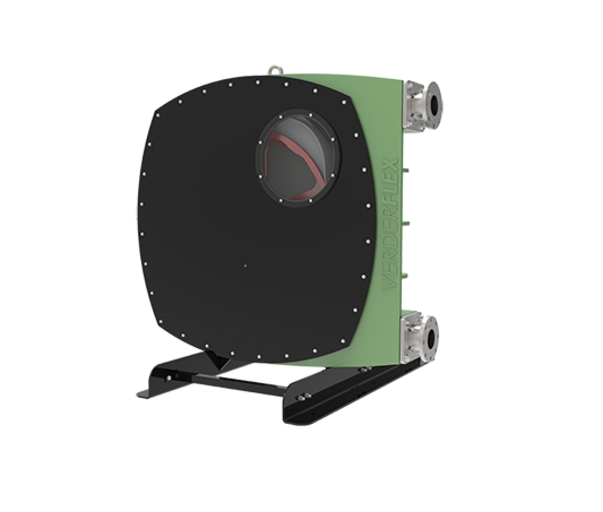

The innovative hose pump is highly compact and easy to maintain. Its unique design reduces the footprint by up to 70% compared to conventional peristaltic pumps. The...

| Max. flow | 33000 l/h |

| Max. (discharge) pressure | 16 bar |

The compact Verderflex iDura is a complete “ready to use", reversible Dura hose pump with factory fitted hose burst protection and an IP66 inverter. IoT enabled with remote assistant.

| Max. flow | 25985 l/h |

| Max. (discharge) pressure | Consult Verderflex |

The Verderflex range of 'VF' industrial peristaltic hose pumps are excellent at handling difficult media such as slurry, sludge, suspensions, solid-laden and...

| Max. flow | 90 m3/h |

| Max. (discharge) pressure | 16 bar |

Verderflex peristaltic pumps are ideal for demanding environments as well as difficult to pump applications. The Verderflex Vantage 5000 for biopharm and...

| Max. flow | 6600 ml/min |

| Max. (discharge) pressure | 7 bar |

The Verderflex Vantage 5000 family is the next generation in cased drive tube pumps combining precision dosing and dispensing accuracy with high discharge pressures,...

| Max. flow | 6600 ml/min |

| Max. (discharge) pressure | 7 bar |

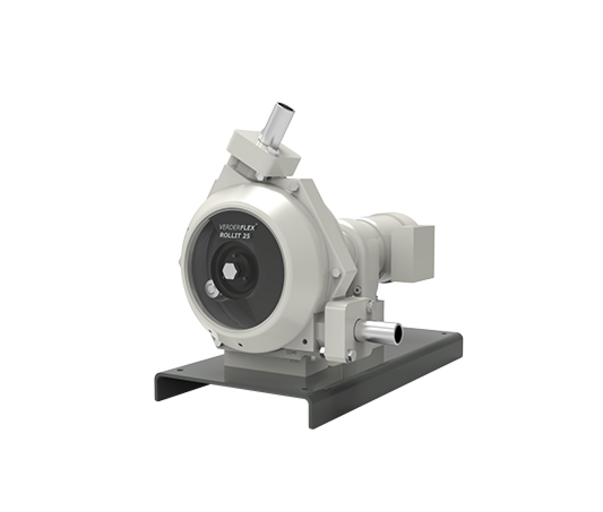

Verderflex ROLLIT pumps are lubricant-free roller peristaltic hose pumps that are easy to maintain and available in a standard (single) and twinhead version.A...

| Max. flow | 24500 l/h |

| Max. (discharge) pressure | 4 bar |

The Verderflex ROLLIT Hygienic is a new family of sanitary dry priming hose pumps, completing the Verderflex range of hose and tube pumps, offering you even more great...

| Max. flow | 6954 l/h |

| Max. (discharge) pressure | 2 bar |

The Rapide is a compact peristaltic tube pump which can be installed as a unit in itself or integrated into a system such as a printing press or packaged turnkey skid....

| Max. flow | 1020 l/h |

| Max. (discharge) pressure | 2 bar |

The Rapide 5000 has been developed to offer simple, reliable and cost effective pumping solutions for industrial applications. The design combines the flexibility of...

| Max. flow | 530 l/h |

| Max. (discharge) pressure | 2 bar |

The Vantage range of peristaltic tube pumps is purpose built for dosing, small transfer and dispensing applications in pharmaceutical, cosmetic, laboratory and...

| Max. flow | 3250 ml/min |

| Max. (discharge) pressure | 2 bar |

Changing a hose on your Verderflex pump is very easy. Please view our online tutorial. If this doesn’t help you, our pump experts can help you!

A peristaltic pump is positive displacement pump that transfers a wide variety of fluids. This pump doesn’t have valves, seals and glands and it’s an inexpensive pump to maintain. Every peristaltic pump features flexible hoses or tubes, giving an open flow path which gives a high resistance to abrasion and permits the easy flow of solids and viscous media. Find our more about how a peristaltic pump works here.

Yes, spare parts are available to order for this pump. We offer maintenance kits, repair kits, dampeners, flow stop valves and all other relevant accessories. You can find more about spare parts here.

Do you need to stock up spare parts or accessories such as lubricants for your Verderflex pump? Let us know what you need below!

In the early 1960s Verder started producing peristaltic pumps. The first series was popular in the emerging Western European chemical and process industry, because the pumps were designed for a long service life to meet the demanding requirements of the often aggressive and corrosive fluids. Verder moved on and designed new series with more functionality, but the clients continued asking for the old VPTV model, so the pump was taken back into production. Until 2 years ago at least one pump was still running; we received a request for spare parts for the VPTV. Of course, we could not meet this request anymore and the pump was exchanged for a Dura 45.

The development of peristaltic pumps continued, in the early 1980s even a series with a dosing computer was developed, a completely unknown phenomenon at the time.

In 1997, another level of production was reached with the development of the first Verderflex VF industrial hose pump. It was the start of a very successful brand of industrial hose pumps. Over the years, the Verderflex product line has grown into a very extensive range of products: from hose pumps with integrated control equipment, to the most precise OEM dosing hose pumps, and to computer-controlled advanced technology pumps.

The Verderflex production site is located in Castleford, UK. With a workforce of 50 high quality pumps are manufactured. The pumps are tested according to an extensive certified test procedure. The magnetically driven centrifugal pumps and the screw channel pumps from Verder are also produced at this Castleford production location.

Our manufacturing company Verderflex specializes in industrial and hygienic tube and dosing pump systems and hose pumps. Verderflex is producing the widest range of peristaltic pumps against the highest industrial and hygienic standards for applications in the food, beverage, biopharma, chemical industry and waste water treatment. The hoses are produced with the highest number of reinforcing layers used in the market. They have proven to have the longest service life of all hoses that are used in the peristaltic pump market.

Verderflex peristaltic pumps have a solid and robust design. They are equipped with the highest quality tubing and hoses. A Verderflex hose has maximum fatigue strength for longest hose life. There is no externally machining used and micro-lubrication pockets cool the hose better for longest hose life.

The huge diversity of hose materials, each with its own specific characteristics, makes it possible to hygienically pump almost any liquid. From long-lasting hoses to single-use tubing for cell cultures: With Verderprene and platinum cured silicone tubing and 21 CFR of FDA hoses Verderflex has a solution for almost every hygienic application.

The hygienic pumps from Verder are problem solvers for the hygienic market. Also the hygienic peristaltic pumps have only one wetted part: the hose or the tube. Verderflex hoses and Verderflex tubing are available in a wide choice of materials.

The Verderlfex advanced dosing systems can be supplied with batch specific certificates of conformity and specific bar-coded labels for use in e.g. biopharma. For Platinum Cured Silicone a comprehensive material validation package is available.

Almost all Verderflex pumps can be equipped with hygienic tubing and hose materials.

Verderflex hose pumps are problem solvers all over industry. They are designed to last and can operate 24/7 in heavy duty applications. They are the pump series for mining, (waste) water treatment, cold pumping process in breweries and many more. Verderflex has lubricated and lubrication-free pump series hose pumps. Also series with integrated frequency inverters.

Verderflex tube pumps are widely used in laboratory scaled projects. Precise tube dosing pumps with a reliable dosing accuracy of +/- 2 %. Series are available from simple dosing applications up to advanced dosing systems with controls such as MODBUS, PROFIBUS and many more.