Packo

The Packo pump range consists of stainless steel centrifugal, lobe and twin screw pumps for hygienic and industrial applications in the food, the pharmaceutical and other general industries. These pumps are built configured to order and tested in our factory in Belgium (Diksmuide). Our pumps rank among the best of the world when it comes to hygiene and cleanability.

About Packo Pumps

Starting in 1975, Packo Pumps has designed and constructed stainless steel pumps for various industries. Packo specializes in industrial stainless steel centrifugal pumps and hygienic rotary lobe pumps and twin-screw pumps. Packo is creating the highest quality centrifugal pumps for industrial, food and pharmaceutical applications.

Curious about the price of a Packo Pump?

Our experts can help you with the right pump for your process!

The Packo pump series

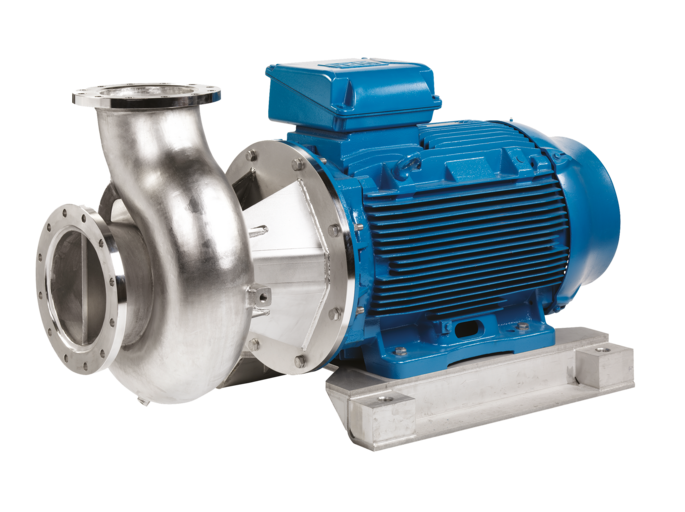

Packo Centrifugal Pumps

Sanitary Pump Series

The Packo sanitary pump series are designed for use in the most demanding hygienic applications in almost all industries such as dairies, breweries, beverage industry, distilleries, etc. They are the ideal solution for filtration applications, pasteurisation, evaporating systems, yeast propagation and for CIP cleaning systems as well.

| Max. flow | 1800 m3/h |

| Max suction lift | 220 m wC |

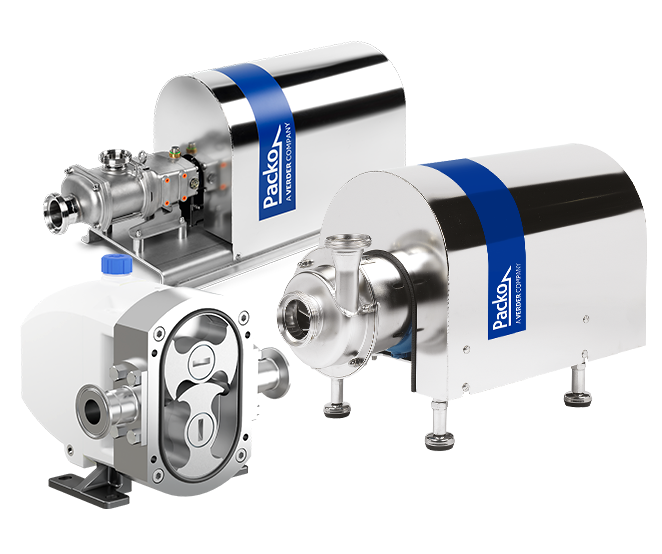

Packo Lobe Pumps

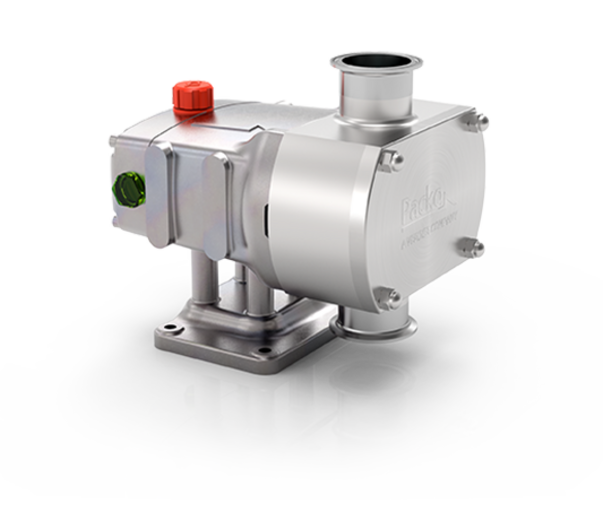

Packo ZL

ZL series are designed for broad applications spectrum covering dairies, foods, beverages, pharmaceuticals, cosmetics, bakeries, detergents, liquors and chemical...

| Max. flow | 1670 l/min |

| Max. (discharge) pressure | 20 bar |

Packo ZLC

The Packo ZLC lobe pump pharmaceutical process pump is 3A certified. These perfectly cleanable pumps can be applied in the most demanding sterile applications in the...

| Max. flow | 1666 l/min |

| Max. (discharge) pressure | 20 bar |

55 Series & Ultima

Fully self-draining pump head: no hold-up of process liquid or cleaning agents. Rapid de-contamination and product change-over. External rotor fixing - no internal...

| Max. flow | 44m³/hr (12 litres/second) |

| Max. (discharge) pressure | 20bar (290 psi) |

HP/LH series Hy~Line(+)

Hy~Line Rotary Lobe pumps are robust, durable pumps designed for long life in demanding applications. Modular construction, using interchangeable ports and feet,...

| Max. flow | 131m³/hr (36.6 litres/second) |

| Max. (discharge) pressure | 15bar (220 psi) |

LT series Hy~Line Tanker Pump

The Hy~Line LT range of truck mounted pumps are used for the loading and unloading of a wide variety of products.

| Max. flow | 684 L/M (lpm) |

| Max. (discharge) pressure | 15 bar |

Packo ZW Rotary Wine Pumps

During red winemaking process, 4~5d ays fermentation and 30~40d ays maceration is needed. The process of fermentation in wine is the catalyst function that turns grape...

| Max. flow | 300 l/min |

| Max. (discharge) pressure | 6 bar |

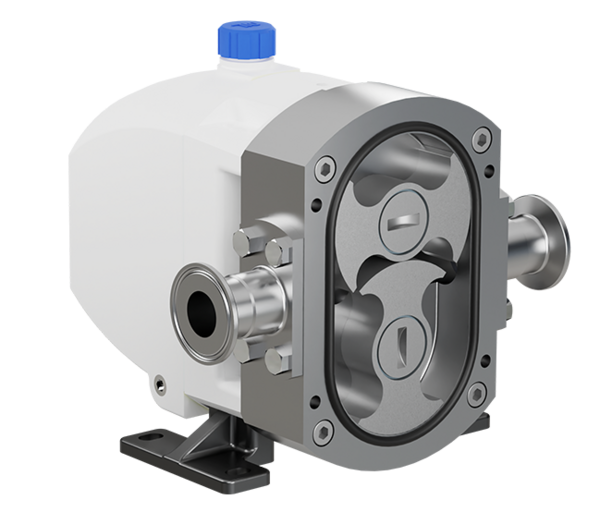

Packo Circumferential Piston Pumps

Packo ZP

Every feature on the ZP range has been specifically designed to make dismantling (whether for inspection, cleaning, or maintenance) quicker, easier and cheaper. What’s...

| Max. flow | 708 l/min |

| Max. (discharge) pressure | 15 bar |

Packo Twin Screw Pumps

Packo ZS

The ZS series can be supplied in diverse types to meet the customer’s requirements. The standard type of ZS Series, the ‘integral type’ consists of integral geared...

| Max. flow | 1660 l/min |

| Max. (discharge) pressure | 12 bar |

Why Choose Packo Centrifugal Pumps?

- High pump efficiency resulting in lower energy consumption

- Low NPSH values: less risk on cavitation

- Electropolished: perfectly cleanable

- Standard components

Frequently Asked Questions

Packo

-

How can I order spare parts?

Write down the serial number of your pump and give us a call! We're always happy to help you.

-

Can I have a pump delivered on short notice?

Please allow 5 working days delivery time for our products.

-

Where are your pumps manufactured?

Our pumps are manufactured in Belgium.

History of Packo Pumps

Starting in 1975, has designed and constructed stainless steel pumps for various industries with a focus on machine builders. Since this date, we have supplied more than 350,000 pumps and these for the most diverse applications.

The first pumps that were developed by us were destined for the dairy industry, so from the outset hygiene and cleanability were a basic requirement for Packo pumps.

The use of stainless steel and the standard applying of an electrochemical surface treatment (electropolishing), find their origin here. These are two factors that make Packo pumps stand out even today. Diversification and deepening of knowledge have led to Packo being a market leader in various sectors today.

Manufacturing Packo Pumps

Since the summer of 2015 Packo belongs to the Verder group. Together we employ 2000 people worldwide spread over different production sites and sales offices. In the factory in Diksmuide we manufacture industrial pumps and hygienic components. There is also an electropolishing division which gives our products a very high degree of finish.

Packo is creating the highest quality hygienic and sanitary pumps for industrial, food and pharmaceutical applications. The centrifugal pumps are manufactured in Belgium. All centrifugal pumps are electropolished according to an in-house developed process method for surface treatment of stainless steel.

The method is finished with hand polishing techniques to achieve the highest quality pump specification for applications where compromise is not an option. Started in 1975 with dairy pumps, Packo Pumps has developed its portfolio to include models for many certified processes including FDA, 3A and EC1935/2004. The rotary lobe pumps and twin-screw pumps are manufactured in South Korea.

With a dedicated team and investment in advancing technology, Verder can offer its Packo pumps as a premium option for compliant applications. The Diksmuide plant produces not only pumps but also static and dynamic mixers.

Types of Packo Pumps

Hygienic Centrifugal Pumps

The hygienic pumps from Verder are problem solvers for the hygienic market. The Packo centrifugal pump series can meet the high requirements of EHEDG and 3A certification. They excel in hygienic cleanability, reliability and are easy to handle. All Packo centrifugal pumps are configured to order, offering a huge range of pump configurations. The standard pumps are used in demanding applications such as dairy, food & beverage and pharmaceutical. This series is also perfectly applicable in industrial applications such as mining, chemicals and waste water. In fact at all duties where a high corrosion resistance is required.

Packo Lobe Pumps

Each series of the Packo rotary lobe and circumferential piston pumps is stateof-the-art. The pumps can be fitted with a variety of features and rotors to adapt to almost all hygienic pumping tasks. The pumps can be customized to meet the optimum function or performance to your process.

Packo Twin Screw Pumps

All advantages of rotary lobe pumps and centrifugal pumps are combined in the Packo twin screw series. This two-in-one operation pump series is excellent for pumping not only high-viscous liquids and pastes but also the thin-liquid cleaning fluids that are used for CIP cleaning. The pumps provide a pulsation free flow for gentle operation.

Jabsco

In May 2021 Verder added the Jabsco lobe pumps to the offering of Verder Liquids into the hygienic market by acquiring the Jabsco lobe pumps from Xylem. Jabsco is a very well-known and established name in the market with a highly loyal customer base and adding the lobe pump product line will fortify our position as a hygienic pump specialist.” All Jabsco lobe pumps can be purchased from the Verder organization under the Packo brand. All other Jabsco product lines and technologies are being retained by Xylem, which continues to serve multiple industrial sectors.

Packo Downloads