Verdergear Process

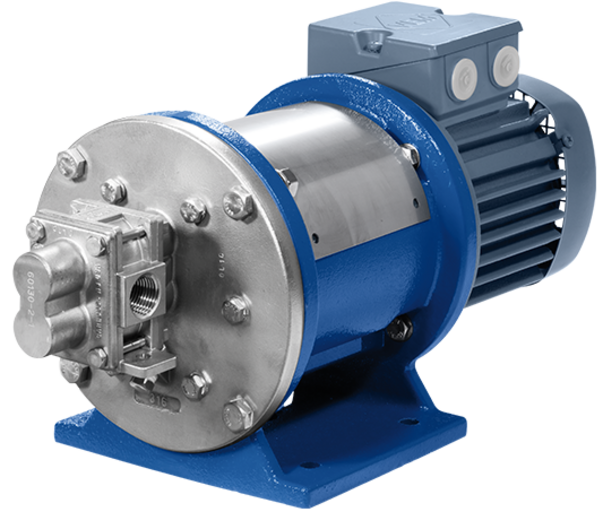

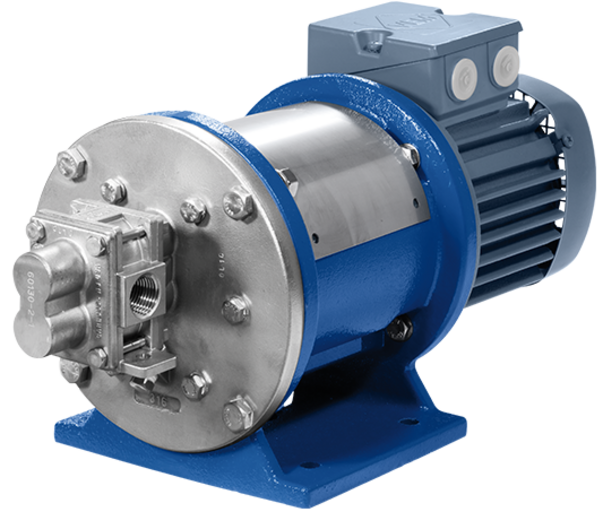

For heavy-duty, industrial applications, the H series provides a robust pump for medium-flow transfer and dosing applications.The pump is constructed to provide a...

| Max. flow | 110 l/min |

| Max. discharge pressure | 15,5 bar |

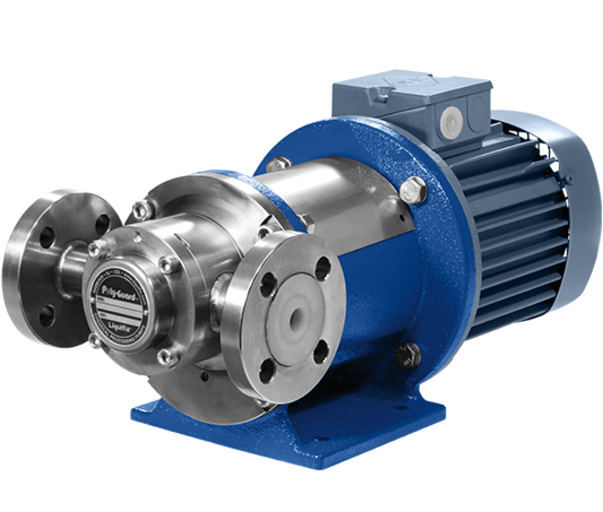

Verdergear by Liquiflo pumps are excellent for demanding applications with hazardous fluids or expensive chemicals. Due to the precise manufacturing tolerances and their linear flow rate, Liquiflo pumps are perfect for dosing applications. Liquiflo gear pumps reduce cost, reduce risk and generate exceptional performance.

A gear pump, is often used for pumping viscous liquids, but is also suitable for other applications. The pumps are excellent for handling of fluids of any viscosity that require a gentle, pulsation-free flow. For heavy-duty, industrial applications, the H series provides a robust pump for medium-flow transfer and dosing applications. The pump is constructed to provide a long service life with sturdy flange connections configured to industrial standards and a robust pump housing and bearing-shaft assemblies sized for significant loads. The ‘H’ series can handle fluids of up to 100,000 mPas. The gear mechanism is available in different tolerances and in high-grade alloy material.

Our experts can help you with the right pump for your process!

For heavy-duty, industrial applications, the H series provides a robust pump for medium-flow transfer and dosing applications.The pump is constructed to provide a...

| Max. flow | 110 l/min |

| Max. discharge pressure | 15,5 bar |

The PFA-Lined gear pumps series offer a durably constructed outer stainless-steel body with a heavily layered Fluoro-Polymer (PFA) internal lining. This highly...

| Max. flow | 56,9 l/min |

| Max. discharge pressure | 7 bar |

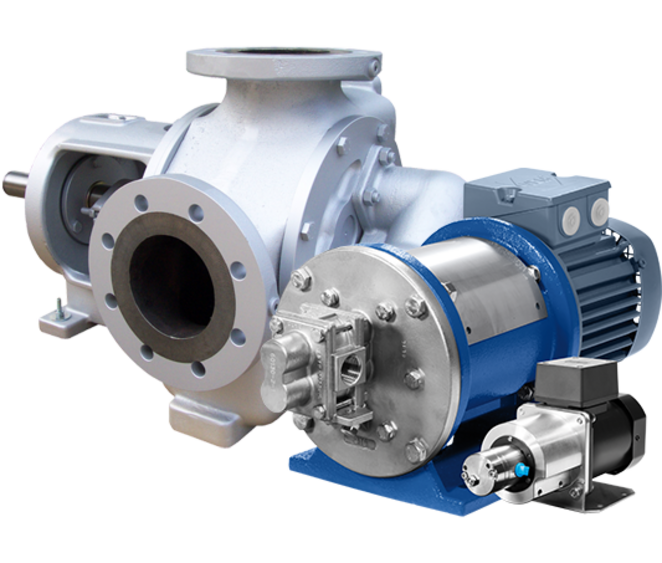

The Verdergear Process Max series gear pumps will handle differential pressures to 24 bar and flows to 76 l/min. Its unique and durable design assures extended life...

| Max. flow | 75 l/min |

| Max. discharge pressure | 24,1 bar |

A Verdergear gear pump is a type of positive displacement pump that utilizes a unique gear design for fluid transfer applications. This pump consists of two intermeshing gears - a driving gear and a driven gear - which create a sealed cavity between them. As the gears rotate, fluid is drawn into the cavity and then expelled through the outlet. The Verdergear gear pump is highly efficient and offers excellent volumetric accuracy, making it suitable for a wide range of applications. It is commonly used in industries such as chemical processing, oil and gas, pharmaceuticals, and food and beverage. The Verdergear gear pump is known for its robust construction, reliable performance, and the ability to handle both thin and viscous fluids with ease. Whether it's for precise metering, dosing, or transferring fluids, the Verdergear gear pump provides a reliable solution for fluid handling needs.

Gear pumps are a reliable choice for pumping high-viscosity fluids in various industrial applications. These pumps are specifically designed to handle thick and viscous liquids with ease, ensuring efficient and consistent fluid transfer. With their unique gear design, gear pumps create tight clearances between the rotating gears and pump housing, allowing for the effective displacement of high-viscosity fluids. They excel in industries such as oil and gas, chemical processing, food processing, and pharmaceuticals, where the pumping of thick oils, polymers, syrups, and other viscous substances is required. Gear pumps offer precise and reliable flow control, minimizing pulsations and ensuring a smooth transfer of viscous fluids. With their robust construction, durability, and ability to handle challenging fluids, gear pumps provide a reliable solution for pumping high-viscosity liquids in demanding industrial environments.

When it comes to accurate dosing pumps, gear pumps stand out for their reliability and precision in various industrial applications. These pumps are specifically designed to deliver precise and consistent fluid doses, making them ideal for dosing applications where accuracy is paramount. The unique gear design of these pumps ensures a consistent displacement volume with each rotation, resulting in accurate dosing of fluids. The tight tolerances between the gears and the pump housing minimize leakage and ensure precise flow control. This level of accuracy is crucial in industries such as chemical processing, water treatment, and pharmaceuticals, where precise dosing of chemicals, additives, or reagents is required. Gear pumps offer the advantages of high volumetric efficiency, low pulsation, and consistent flow rates, enabling them to provide reliable and accurate dosing of fluids. With their precise dosing capabilities, gear pumps contribute to improved process control, enhanced product quality, and cost-effective operations in a wide range of industrial applications.

In the chocolate manufacturing industry, gear pumps play a crucial role as specialized transfer pumps for effectively handling chocolate. These pumps, specifically designed to accommodate the unique properties of chocolate, including its viscosity and temperature sensitivity, ensure precise and controlled transfer throughout various production processes like tempering, enrobing, and molding. With their gentle pumping action, gear pumps preserve the texture and quality of the chocolate. By providing accurate dosing and maintaining consistent flow rates, these gear pumps are indispensable in ensuring efficient chocolate production and the creation of high-quality chocolate products.

Starch pumps, including gear pumps, are vital for efficiently handling and transferring starch-based materials. Specifically designed for the thick consistency and high viscosity of starch, these pumps ensure reliable and precise transfer during various production processes. Widely used in food processing, paper manufacturing, and textile production, starch pumps play a crucial role in achieving efficient starch processing and the production of high-quality starch-based products.

Heating jackets for pumps are essential for precise temperature control in industrial processes. These jackets envelop the pump housing, ensuring optimal fluid viscosity and preventing freezing or solidification. Widely used in various industries such as oil and gas, chemical processing, pharmaceuticals, and food production, heating jackets optimize pump efficiency and promote consistent fluid flow.

Relief valves are essential safety devices used in various industries, including those utilizing gear pumps. These valves automatically open to relieve excess pressure, safeguarding equipment and systems from damage or accidents. Widely employed in industries like oil and gas, chemical processing, and manufacturing, relief valves ensure safe operating conditions and protect gear pumps, pipelines, and personnel. Their ability to respond to pressure fluctuations and maintain system integrity makes relief valves crucial for maintaining safety and operational efficiency in industrial settings.