Centrifugal Pump

Discover the capabilities of a centrifugal pump and

how it can be the right solution for your application.

Do you have questions about our centrifugal pump range?

One of our pump experts is here to support you.

Centrifugal pump

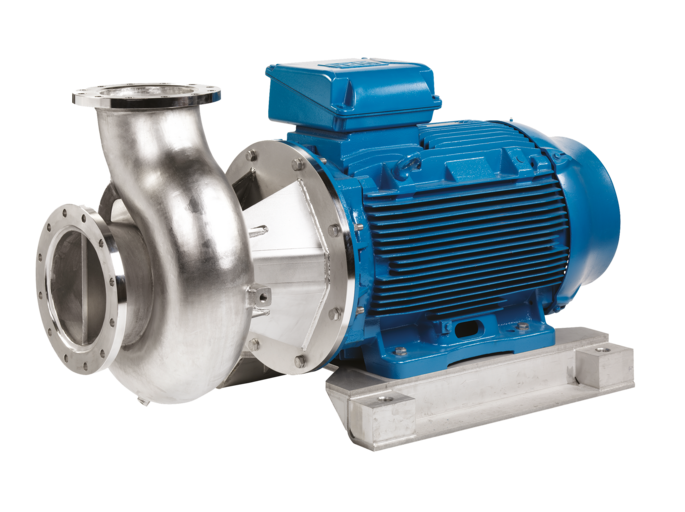

Our range of Packo centrifugal pumps are known for their outstanding craftsmanship and technological innovation. Made from stainless steel, they are suitable for a range of applications ranging from industrial, hygienic, to pharmaceutical and more. Below you will find everything about a centrifugal pump, its working principle, benefits and reasons to use and a breakdown of the applications where this type of pump excels at.

How does a Centrifugal Pump work?

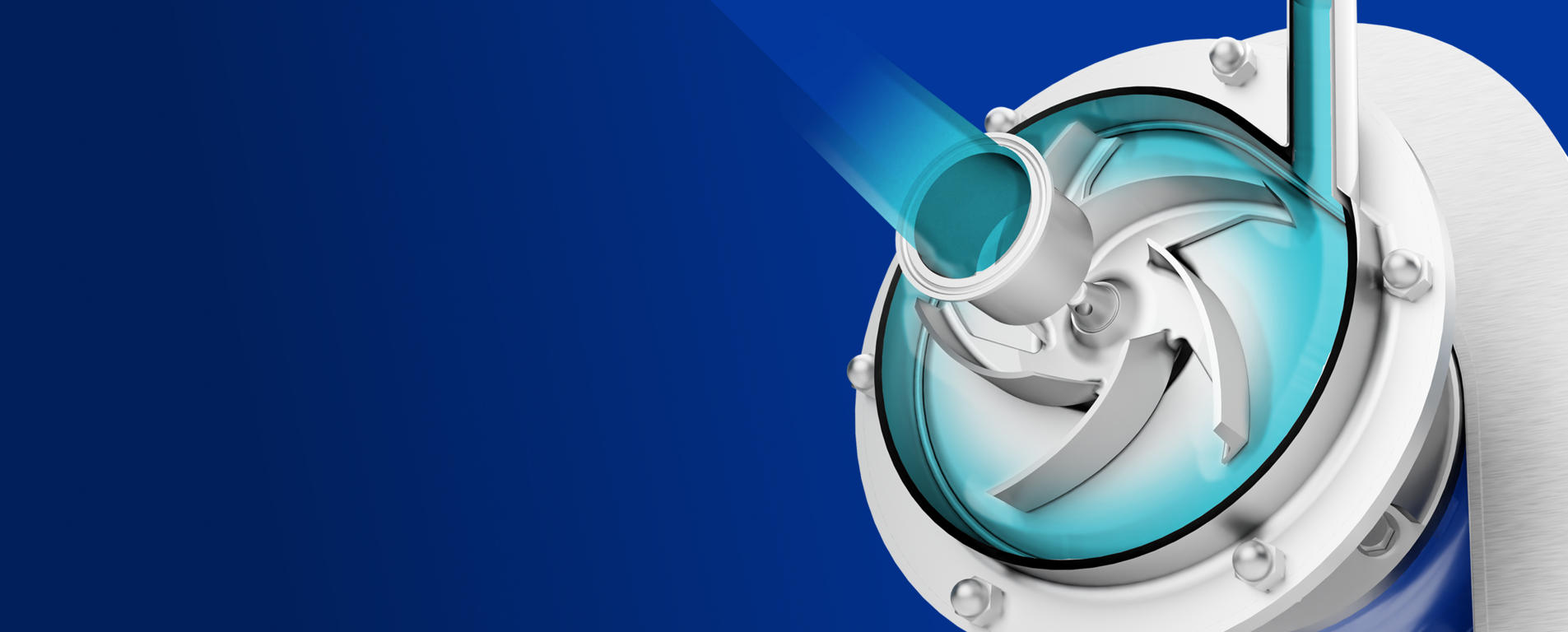

A centrifugal pump works on the principle of a rotating impeller within a stationary pump housing. The impeller is connected to a shaft and powered by a motor. As the impeller turns, it moves the liquid out of the pump through centrifugal force, exiting through the discharge flange.

What is the working principle of a centrifugal pump?

A centrifugal pump operates on the principle of centrifugal force to move fluid. How does this translate to operation?

- Impeller Rotation: When the pump starts, the motor drives the impeller to rotate. The impeller has a series of curved vanes.

- Fluid Intake: Fluid enters the pump through the eye of the impeller. This area is at lower pressure compared to the rest of the system, allowing fluid to be drawn into the pump.

- Centrifugal Force: As the impeller rotates, it imparts velocity to the fluid due to centrifugal force. The fluid is pushed radially outward from the impeller eye to its periphery.

- Conversion of Energy: The kinetic energy (velocity) of the fluid is converted into potential energy (pressure) as it slows down in the volute casing or diffuser. The volute casing is a spiral-shaped channel that gradually expands in cross-sectional area, allowing the fluid to slow down and its pressure to increase.

- Discharge: The pressurized fluid is then directed towards the pump outlet or discharge port, where it exits the pump.

Question about how centrifugal pumps work?

Do you need help? Our pump experts are there for all your questions!

Benefits of a Centrifugal Pump

- Cleaner & more resistant

- Lower energy bills

- Shortest downtimes

- Low energy consumption

Our Packo centrifugal pumps

Centrifugal Pump Applications

- Food Industry: Our Packo centrifugal pumps are used for various stages in food processing, including transport and reception of vegetables, de-stoning, peeling, cutting, blanching, and canning. They are designed to meet high hygienic standards with certifications such as EHEDG and 3A.

- Dairy Industry: Packo pumps in this sector are tailored for applications with high hygienic requirements. They excel due to their respective hygienic certificates

- Pharmaceutical, Cosmetic, Biotech, and Semiconductor Industry: These industries utilize our pumps for their high mechanical surface polish and electropolishing standards, ensuring the highest quality for sensitive applications.

- General Industry: Our pumps also serve general industrial needs, including water treatment processes and biogas applications, highlighting their versatility.

Why choose a Packo Centrifugal pump?

Choosing a Packo centrifugal pump offers several advantages

- Optimal Energy Balance: Packo pumps are designed with optimal pump hydraulics, ensuring the best energy balance and efficiency in operation.

- Electropolished Surface Treatment: The pumps undergo an in-house developed electropolishing process, providing a high-quality finish that meets stringent hygienic standards for sensitive applications.

- Modular Design: The pumps feature a modular design, allowing for easy maintenance and adaptability to different applications.

- Material Quality: Constructed with 316L stainless steel, Packo pumps are durable and suitable for a wide range of industrial and hygienic applications.

- Certified for Hygienic Processes: Packo pumps have certifications such as FDA, 3A, and EC1935/2004, making them ideal for food, dairy, pharmaceutical, and other hygienic applications.