How do Lobe Pumps work?

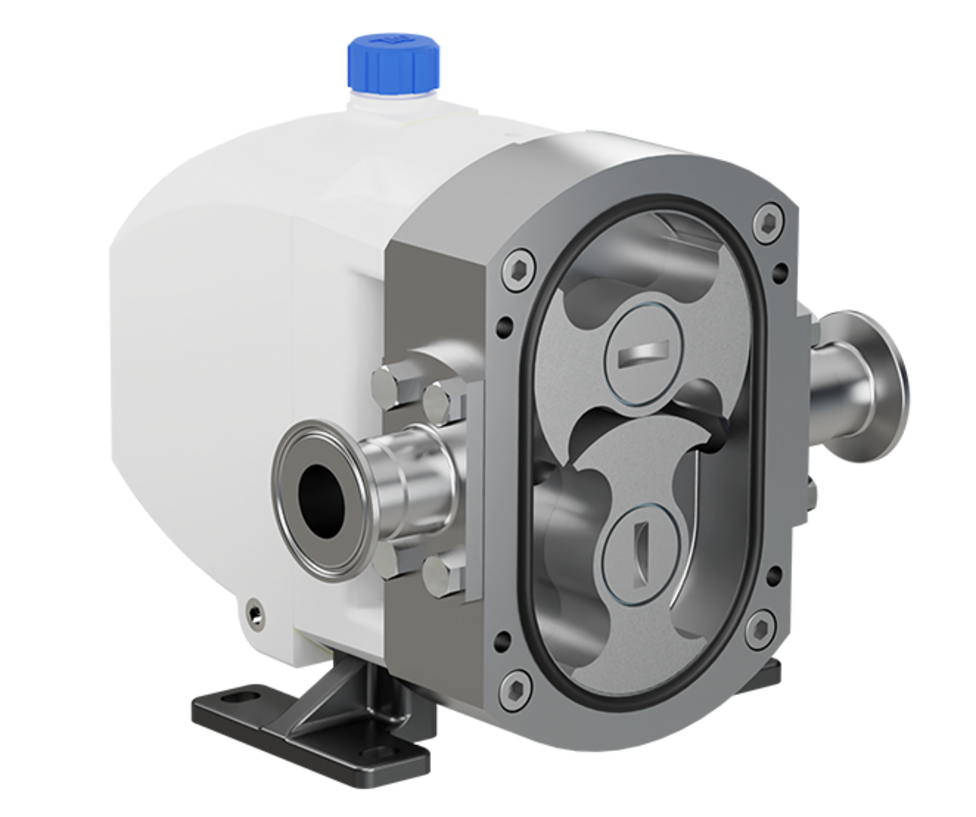

All rotary lobe and circumferential piston pumps are designed according to the same construction principle. Two displacement elements (3) mounted on parallel shafts (1) are supported by an external gearbox (5).

The two displacers (3) turn in opposite direction with minimal radial and axial clearances. They neither touch each other nor the surrounding pump casing. The shafts are synchronized by spur gears. (4)

The displacers (3) are shaped so that they seal the suction chamber against the pressure chamber in any position. This sealing is only achieved by the gap, not by additional seals or valves. The removable pump cover (2) seals the pump housing and allows easy access from the front.

Working principle Lobe and Piston Pumps

1. The volume at the inlet increases when the rotors rotate, and the product is aspirated into the pump

2. The liquid is transported between rotor and casing (chamber) through the pump

3. The volume is reduced between the rotors and the product is forced out through the outlet

Advantages Lobe Pumps

✔ Damage free: Often used in food applications because lobe pumps handle solids without damage to the product

✔ Larger particle size: the particle sizes that can be pumped are often larger in lobe pumps then in other positive displacement pumps

✔ Low viscosity liquids can be handled with diminished performance

✔ No metal to metal contact

✔ Suitable for hygienic applicatins due to superior CIP/ SIP capabilities

The core benefits of using a lobe pump are the perfect cleaning capabilities, the ease of maintenance and the extended life time thanks to the improved construction. Lobe pumps mean reliable and safe pumping of food and pharma related fluids.

Applications Lobe Pumps

Lobe pumps can be used in a variety of applications, like below, but are not limited to:

- Polymers

- Paper coatings

- Soaps and surfactants

- Paints and dyes

- Pharmaceutical applications

- Food applications

What are the benefits of Packo Lobe Pumps?

These positive displacement pumps are perfectly suited for pumping hygienic products with higher viscosities. When the product becomes more viscous, the efficiency of this pump also increases.

This lobe pump technology has the greatest flexibility regarding the shape of the rotor in function of the product to be moved. They can be equipped with a single-, double-, tri-, multi-, piston circumferential- or helical lobe. The single and double lobes can be used when a larger free passage is required, while the trilobes and multilobes come into play for the more dosing-oriented applications. The Helilobe in turn guarantees a pulsation-free operation, low NPSHr and the flexibility to work with high and low viscosity at different speeds, all in a nice TCO jacket.

Besides these standard stainless steel versions (316L), rubber rotors are also available which find their application in the wine industry or also alloys which allow a metallic contact between rotor and pump casing without damage (non galling rotors).

With the configure to order principle, the Packo lobe and piston circumferential pumps can be complete executed to the customer's wishes. Multiple connections, seal configurations and various elastomers applicable.

Want to know more about how Packo pumps can help you?

Do you need help? Our pump experts are there for all your questions!