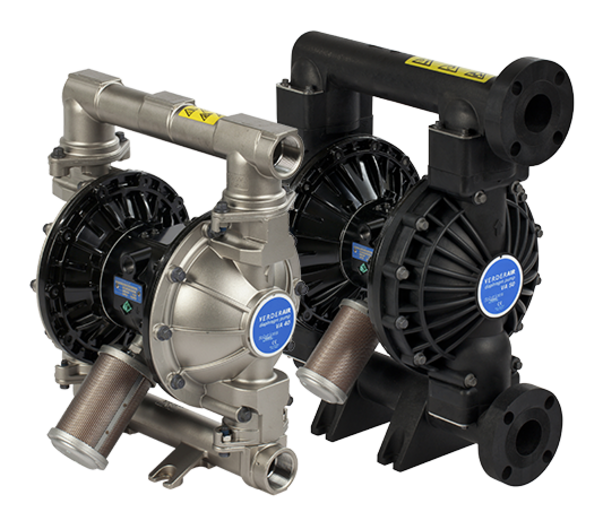

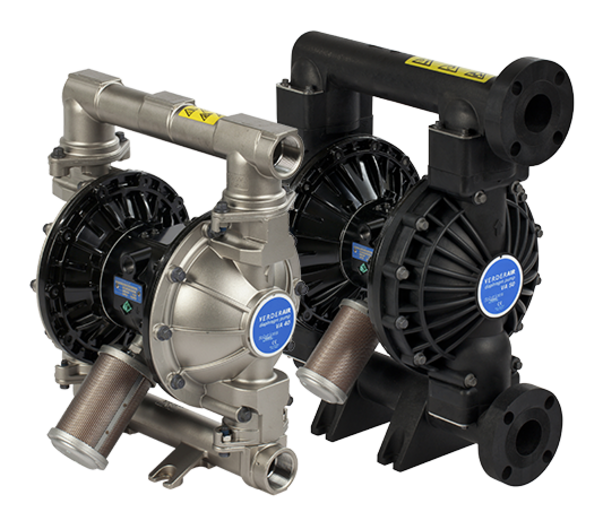

Verderair VA

The VA industrial range really does set the benchmark for air diaphragm pumps. The range features fast-acting air valve technology – eliminating wasted air and using...

| Max. flow | 1200 l/min |

| Max. discharge pressure | 8,6 bar |

Discover the capabilities of a diaphragm pump and

how it can be the right solution for your application.

Do you have questions about our diaphragm pump range?

One of our pump experts is here to support you.

A diaphagm pump, also knows as a membrane pump, is a positive displacement pump that enables users in industries to standardise on a pump type that is suitable for a wide variety of fluids. Verderair diaphragm pumps, manufactured in-house and to the highest standards in the industry, are available in different materials, both metallic and non metallic, to suit any specific needs in fluid handling, no matter how difficult.

A diaphragm pump operates by using a flexible diaphragm that moves back and forth to create a variable volume within the pump chamber. As the diaphragm moves up, it creates a vacuum, drawing fluid into the chamber. When the diaphragm moves down, it pushes the fluid out of the discharge valve. This type of pump is often used for its reliability and ability to handle various fluids without contamination, as the fluid does not come into contact with moving parts like gears or pistons.

Our Verderair range consists of two different types of diaphragm pump, air operated double diaphragm pumps, and electrically driven double diaphragm pumps. As their names imply, the key difference between the two would be the way the operate, with the former being driven by compressed air, while the latter is operated using an electric motor.

Do you need help? Our pump experts are here to answer your questions!

The VA industrial range really does set the benchmark for air diaphragm pumps. The range features fast-acting air valve technology – eliminating wasted air and using...

| Max. flow | 1200 l/min |

| Max. discharge pressure | 8,6 bar |

The Verderair PURE is designed for heavy-duty operation, harsh chemicals and severe process conditions, such as the manufacturing of photovoltaic solar panels, power...

| Max. flow | 660 l/min |

| Max. discharge pressure | 7 bar |

The Verderair HC-PURE series of hygienic double diaphragm pumps is designed for various hygienic applications. The electropolished surfaces reduce the risk of bacteria...

| Max. flow | 465 l/min |

| Max. discharge pressure | 7 bar |

Our diaphragm pumps have high versatility and reliability in handling a diverse range of fluids and in varying conditions. Some of the applications include