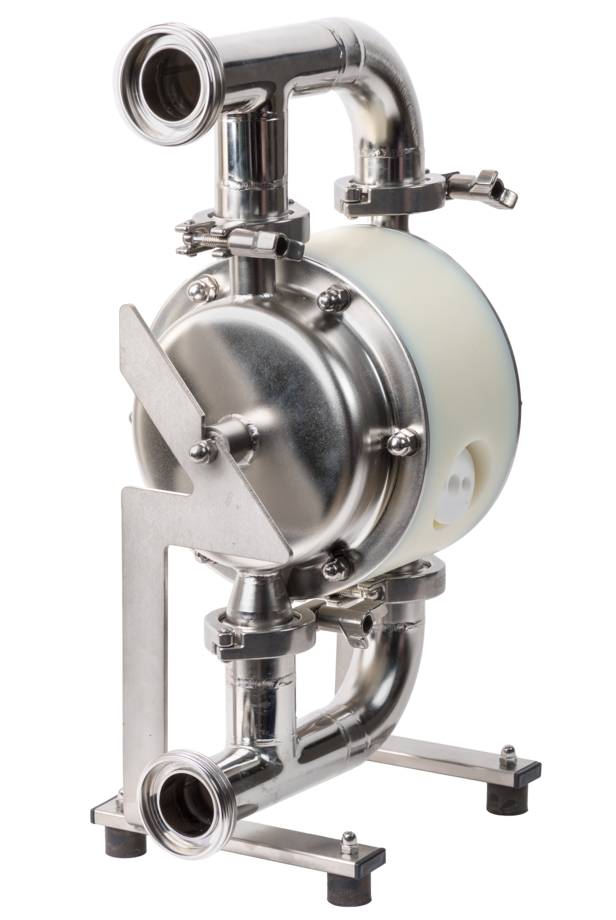

Are you killing your diaphragm pump?

You could be killing your diaphragm pump without even knowing it! Download your free copy of our whitepaper '10 Ways to Kill your Diaphragm Pump' and discover all about:

- How incorrect usage can reduce the life cycle

- A detailed explanation of the factors that could be ruining your diaphragm pump

- Helpful tips on how to avoid destroying your diaphragm pump

1. Run the pump dry without limitations

Dry running an air-operated double diaphragm (AODD) pump may not immediately damage the pump, but it can accelerate wear and lead to premature failure. When an AODD pump runs dry, it operates at a higher speed, resulting in increased air consumption and more frequent diaphragm strokes. This can cause the diaphragms to lose their elasticity more quickly and ultimately fail.

To prevent this issue, you can use a Flow Stop Valve in the air supply to the pump. This valve detects increased air consumption and automatically closes off the air supply to the pump, protecting it from damage due to dry running.

2. Run the pump with dirty and/or very humid air

Air moisture and quality are crucial factors for the proper operation of air-operated equipment. High moisture or poor air quality can lead to issues such as icing or clogging of the air valve or muffler in an air-operated double diaphragm (AODD) pump. Moisture in the air can condense in the air exhaust due to temperature drops from high to low pressure, leading to clogging of the muffler. Additionally, accumulated waste over time can also contribute to clogging.

To avoid these problems, it’s essential to use clean, dry, and filtered air to operate the pump. Regularly checking the muffler for dirt buildup and monitoring the quality of the air supply is also important. If the plant air quality is poor, consider using an Anti-Ice Muffler and installing an air filter in the compressed air line before the pump. These measures will help ensure error-free operation of the pump and prevent issues related to moisture and air quality.