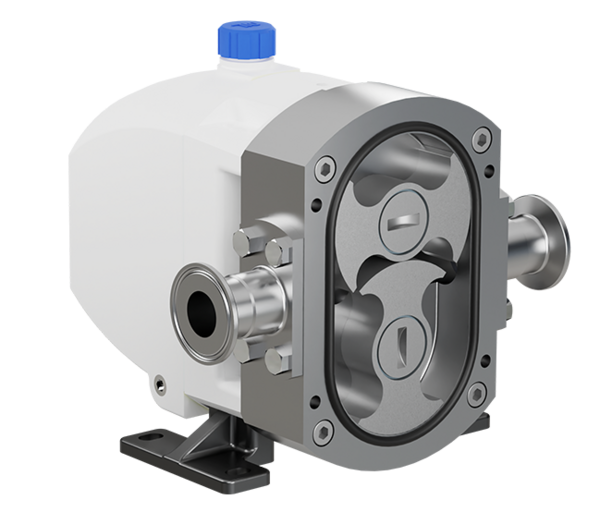

Packo ZL

Drehkolbenpumpen der Serie ZL sind für ein breites Anwendungsspektrum wie Milchprodukte, Lebensmittel, Getränke, Arzneimittel, Kosmetik, Teigwaren, Waschmittel,...

| Max. Fördermenge | 1670 l/min |

| Max. Förderdruck | 20 bar |

Entdecken Sie die Fähigkeiten von Drehkolbenpumpen und wie

Sie können die richtige Lösung für Ihre Anwendung sein.

Haben Sie Fragen zu unserem Drehkolbenpumpenprogramm?

Einer unserer Pumpenexperten ist hier, um Sie zu unterstützen.

Drehkolbenpumpensind eine Art Verdrängerpumpe, die sich gut zum Fördern viskoser Flüssigkeiten eignet. Der Wirkungsgrad einer Drehkolbenpumpe steigt mit der Viskosität des zu fördernden Produkts. Sie sind bekannt für ihre Flexibilität, ihren pulsationsfreien Betrieb und ihre Fähigkeit, sowohl hoch- als auch niedrigviskose Flüssigkeiten bei verschiedenen Geschwindigkeiten zu verarbeiten. Auf dieser Seite erfahren Sie, wie eine Drehkolbenpumpe funktioniert, wie sie funktioniert und in welchen Anwendungen sich Drehkolbenpumpen auszeichnen und wie groß unser Sortiment an Packo-Drehkolbenpumpen ist.

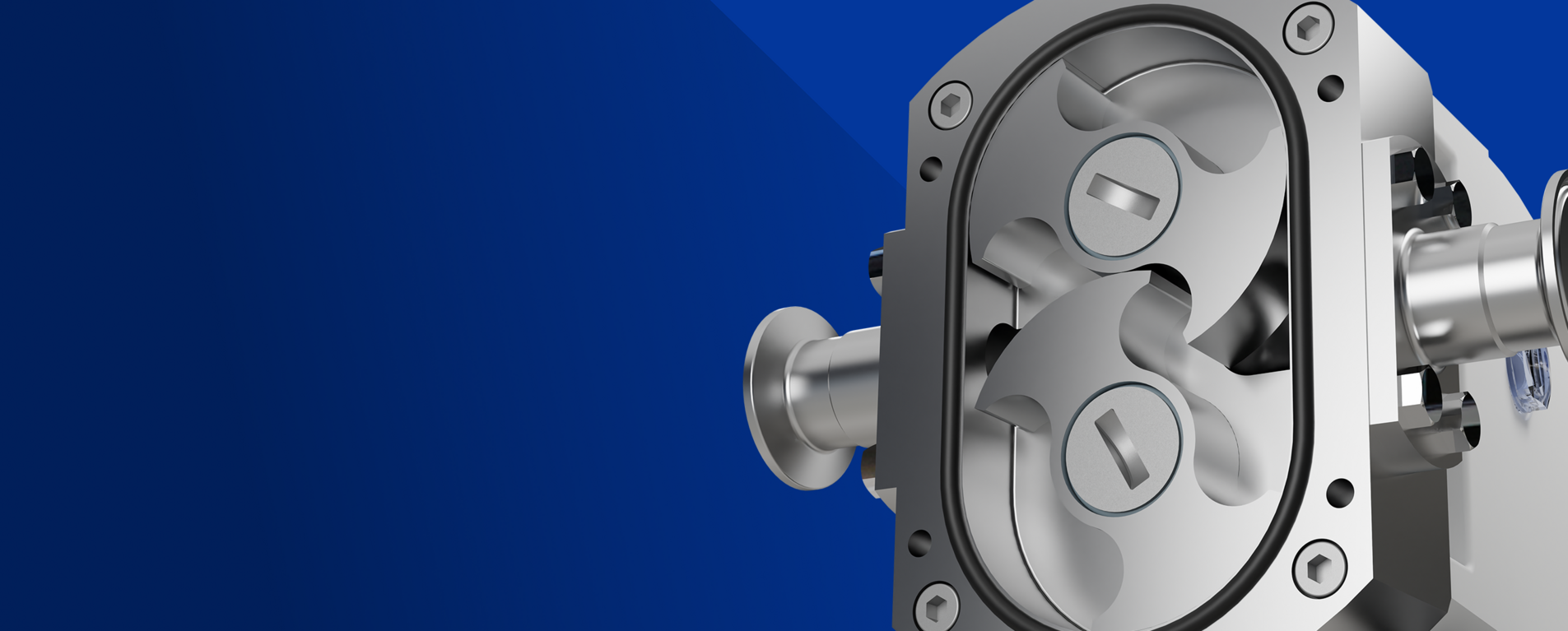

Eine Drehkolbenpumpe arbeitet mit zwei Kolben, die man sich als Zahnräder vorstellen kann und die sich innerhalb eines Gehäuses in entgegengesetzte Richtungen drehen. Diese Nocken werden in der Regel von externen Zahnrädern angetrieben, die sicherstellen, dass sie sich synchron mit einem kleinen Abstand zwischen ihnen drehen, wodurch ein direkter Kontakt vermieden wird. Dadurch entsteht dann ein Vakuum, das schließlich die Flüssigkeit ansaugt. Die Flüssigkeit wird dann in den Zwischenräumen zwischen den Kolben und dem Pumpengehäuse eingeschlossen und dann zur Druckseite transportiert. Hier wird die Flüssigkeit beim Ineinandergreifen der Kolben aus der Pumpe gedrückt. Das folgende Video zeigt Ihnen dies in Aktion mit einem PackoHP/LH Hy~Line.

Drehkolbenpumpen arbeiten nach dem Funktionsprinzip von zwei Rotoren, die sich in entgegengesetzte Richtungen drehen, wobei die Flüssigkeit in die Pumpe eintritt und den Raum zwischen den Rotoren ausfüllt. Wenn sich die Rotoren drehen, wird die Flüssigkeit an der Außenseite der Pumpenkammer herumtransportiert und aus der Auslassöffnung herausgedrückt, während die Rotorkolben ineinander greifen. Diese Pumpen können mit verschiedenen Rotorformen ausgelegt werden, z. B. Einzel-, Doppel-, Drei-, Mehrkolben-, Umfangs- oder Spiralkolben, um den spezifischen Anwendungs- und Produktanforderungen gerecht zu werden.

Brauchen Sie Hilfe? Unsere Pumpenexperten sind hier, um Ihre Fragen zu beantworten!

Drehkolbenpumpen der Serie ZL sind für ein breites Anwendungsspektrum wie Milchprodukte, Lebensmittel, Getränke, Arzneimittel, Kosmetik, Teigwaren, Waschmittel,...

| Max. Fördermenge | 1670 l/min |

| Max. Förderdruck | 20 bar |

Vollständig selbstentleerender Pumpenkopf: kein Rückhalten von Prozessflüssigkeit oder Reinigungsmitteln. Schnelle Dekontamination und Produktwechsel....

| Max. Fördermenge | 44m³/hr (12 litres/second) |

| Max. Förderdruck | 20bar (290 psi) |

Packo Hy~Line-Drehkolbenpumpen sind robuste, langlebige Maschinen, die für lange Lebensdauer in anspruchsvollen Anwendungen ausgelegt sind. Die modulare Konstruktion...

| Max. Fördermenge | 131m³/hr (36.6 litres/second) |

| Max. Förderdruck | 15bar (220 psi) |

Unsere Drehkolbenpumpen sind vielseitige und zuverlässige Lösungen für die Förderung viskoser Flüssigkeiten. Einige der Anwendungen umfassen:

Die Entscheidung für eine Packo-Drehkolbenpumpe bietet mehrere Vorteile für Ihre Prozesslinie und gewährleistet eine langlebige, kostengünstige und hygienische Lösung. Hier sind einige Gründe, die Sie in Betracht ziehen sollten: