Case study: pumping cheese curd in hard cheeses

Is your pump also ruining you?

Note: this case study is only applicable for hard cheeses

There are some stubborn prejudices about what is the right pump in a hard cheese production process. If these prejudices are not correct, cheese producers will not get the most out of their process. This for both the efficiency of the process and the quality of the product.

That is why we have investigated whether these prejudices contain any truth and this in collaboration with a producer of Emmental cheeses.

At the same time, we also tried to solve a common problem in the production process of hard cheeses. The production of hard cheeses often results in an undesirable side product, namely curd fines.

This side product is preferably avoided as it has a negative effect on the quality of the cheese and consequently the cheese producer's yield. The point is: the more of this side product (curd fines) is produced, the less of the main product (the cheese itself) remains.

One of the main reasons for the formation of curd fines is pumping the product too roughly. No wonder, therefore, that the choice of pump plays a major role in the prevention of curd fines.

With a concrete practical example, we would like to demonstrate how a correct pump selection solves this problem and at the same time increases the quality and efficiency of the process.

Current vision on the market

At present, there are about 4 different types of pumps in the production process for hard cheeses:

- Monotype pump

- Sinus pump

- Lobe pump

- Vortex pump (centrifugal pump with vortex impeller)

It is generally assumed that vortex pumps and lobe pumps are the best pumps to avoid curd fines. Let us take a closer look at these 2 types of pumps.

Firstly, lobe pumps. These have the advantage that they run slowly and do little damage, but the disadvantage is that they are rather expensive (especially for large flow rates higher than 50 m³/h). Moreover they even need a separate CIP pump (CIP = cleaning in place).

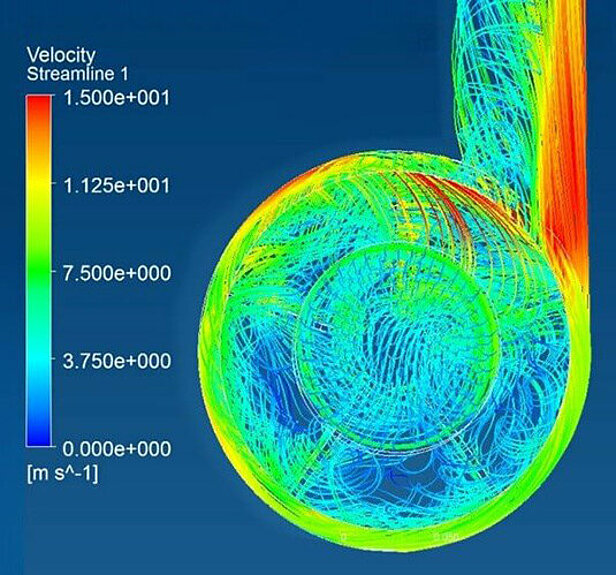

Secondly, vortex pumps, these are a type of centrifugal pumps with recessed impeller (vortex impeller) that has straight blades and a pump housing that is completely round (Figure 1).

It is assumed that the recessed impeller ensures that the curd is not going "through" the impeller and therefore less damaging than an ordinary impeller.

But are these assumptions correct or are they prejudices?

Possible alternatives?

Is a vortex pump really the best solution for this problem? In approaching this question we kept the following in mind:

"A pump with the highest possible efficiency will ensure a smoother pumping of the medium and thus less damage to the curd"

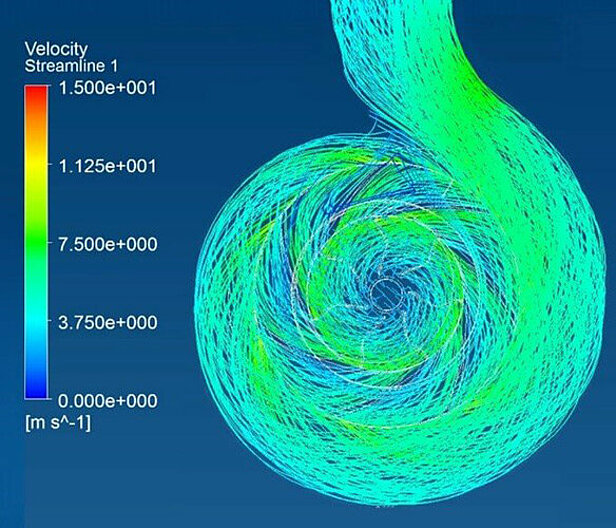

To come to an alternative, we used our CFD system (= Computational Fluid Dynamics). This software makes it possible to simulate the medium in the pump. Which gave us the opportunity to improve following points:

- Reducing the turbulence;

- Increasing efficiency

- What will result in a generally softer pumping of the medium.

This study led us to a Packo pump with the following characteristics:

- High efficiency pump;

- Pump casing with volute shape;

- Closed impeller with 3D blades.

In a next step we compared our solution with the usual vortex pump and that at the same operating point: 60 m³/h at 7m. This gave the following result:

Vortex impeller

- Velocities > 15 m/s

- Dead zones

- Large variation in speed

- Efficiency: 58%

⇒ Brusque pumping

Closed impeller

- Velocities < 7 m/s

- No dead zones

- Small speed variation in the pump

- Efficiency: 75%

⇒ Soft pumping

So what quickly became clear from this test is that a closed impeller achieves a higher efficiency than the often used vortex impeller.

In the standard range of Packo we offer 2 pumps that meet these characteristics, the FP3 and MFP3. These pumps could therefore be used for our test at the customer.

In practice

For this research we have worked closely with a customer who produces Emmental cheese. Like most cheese producers, they also used vortex pumps in their production process.

Before the test was carried out with Packo, the customer had already tried a number of things himself:

- Set a lower and higher speed of the pump;

- Longer and shorter filling time set;

- Different pressure at the filling nozzle (0.25 - 0.5 bar);

- Filling nozzle with different diameters (17 – 22 mm).

All these adjustments showed no clear improvements as expected, in some cases a reduction in quality was observed. A lesser quality of cheese is also noticeable by the following characteristics:

- Presence of curd fines at various places on the surface, causing problems during the pressing of the young cheese with the separation of solid (curds) and liquid phase (whey);

- Uneven filling of the mold;

- Cheese rounds that are thinner in the centre than on the outside;

- Cheese rounds with different weight;

- Cracks in the cheese.

Research goals

In order to be able to speak of a successful exercise, our client had set the following objectives:

- Filling time of the cheese mold about 12-13 min;

- The pressure on the filling nozzle (dispenser) is always between 0.30-0.35 bar;

- Equal distribution of the curd in the different cheese rounds (6, 8 & 10);

- No curd fines;

- The same weight for all cheese rounds (ca. +/-3kg);

- Consistent filling (symmetrical);

- Quality of the cheese matches the market requirements (number of holes, durability & shelf life).

System parameters practical test

In the meantime, an evaluation of the entire installation was made at the customer's premises. In order to determine which pump and under which circumstances it would achieve the best result. To be able to make an optimal selection in this way.

- Targeted operating point: 60m³/h @8,6m.

- Pump selection a Packo FP3/100-250 pump with the following characteristics:

- Motor of 5,5kW – 6-polig (1000 rpm => 700 rpm);

- Closed impeller;

- Pump efficiency of approximately 75% at the operating point.

This pump was used in the production process at the cheese factory and subjected to various tests to investigate the optimal settings. This is necessary as different types of cheese are used (6/8/10) that require different speeds and operating points.

Below you will find an overview of the settings that have been tested and what the final results have become.

| Test phase | Final setting |

|

|

Pressure at the dispenser |

0.1 – 0.6 bar |

0.30 – 0.35 bar |

|

Filling time |

9-13 minutes |

12 minutes |

| Pump velocity | Different speeds | 600 to 700 RPM |

Did the pump cope well?

Now the most important thing remains. Did the test show positive results at the customer?

After entering the FP3 pump in the production process, we saw the following results:

- No more losses as a result of curd fines;

- Symmetric cheeses;

- The same weight of cheese in the production of the various cheese rounds (6, 8 & 10);

- Quality of the cheese matches the market requirements (number of holes, durability & shelf life;

- Very low noise level during pumping of the curd

Even better, all these changes ensured that after 3 (!) months the pump had repaid itself.

A good pump selection therefore had a positive impact on the entire production process: from the efficiency of the process to the quality of the cheeses themselves.