Rotary Gear Pumps

Discover the capabilities of rotary gear pumps and

how they can be the right solution for your application.

Do you have questions about our rotary gear pump range?

One of our pump experts is here to support you.

What are Rotary Gear Pumps?

Rotary gear pumps are a type of positive displacement pump that use the meshing of gears to pump fluid by displacement. They are designed to handle a wide range of viscosities and are commonly used in various industries for their reliability and efficiency. Some of these industries include the pharmaceutical, food and beverage, as well as the chemical industry,

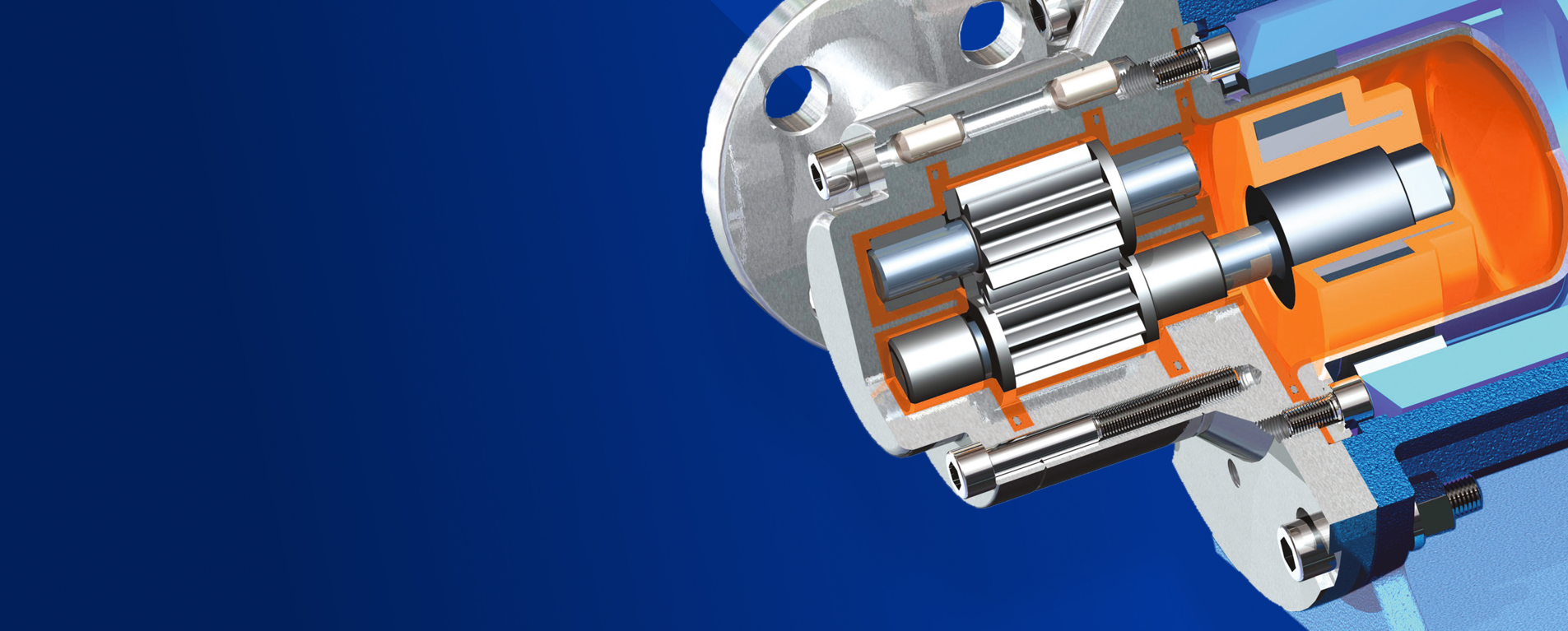

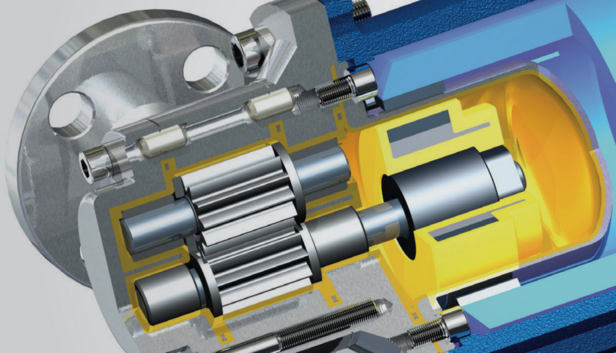

How do rotary gear pumps work?

The pumping principle of rotary gear pumps consists of two gears, one driving and one driven, which rotate in opposite directions. As the gears rotate, they create a void at the inlet, allowing fluid to flow in. The fluid is then trapped between the gear teeth and the pump casing, and as the gears continue to rotate, the fluid is carried around the casing to the outlet, where it is discharged. This design ensures a smooth and consistent flow, making rotary gear pumps ideal for applications requiring precise and steady fluid delivery.

Benefits of Rotary Gear Pumps

- Safe and leak-free

- Virtually no pulsation

- Low NPSHr

- Wide range of viscosity

Applications of Rotary Gear Pumps

- Chemical Industry: Rotary gear pumps are used for handling a wide range of chemicals, including corrosive and abrasive fluids. Their precise metering capabilities make them ideal for dosing and transferring chemicals in processes that require accuracy and consistency.

- Food and Beverage Industry: Our rotary gear pumps are employed in the food and beverage sector for tasks such as dosing flavors, syrups, and other ingredients. Their hygienic design and FDA-approved materials ensure that they meet the stringent safety and quality standards required in food processing.

- Water Treatment: Rotary gear pumps are also used in water treatment applications, where they help in the dosing of chemicals for water purification and treatment processes. Their robust construction and reliable performance make them suitable for continuous operation in demanding environments.

Technical Specifications of Rotary Gear Pumps

A rotary gear pump's technical specifications highlight their exceptional design and functionality. Mag-drive external gear pumps are engineered for safe and leak-free pumping of both high and low viscous fluids, making them ideal for metering and dosing applications due to their virtually pulse-free flow. Verdergear pumps offer a wide flow range, making them suitable for various applications. They also have a low NPSHr requirement, which allows for the use of smaller pipe diameters, thereby reducing the Net Positive Suction Head required. Constructed from high-quality materials, Verdergear pumps ensure durability and reliability across different industrial environments.